In heavy-duty machinery, power and precision define productivity. Your machine’s transmission is its powertrain’s heart—it converts raw engine output into usable torque. But if the transmission is the heart, the valve body is its brain and control system.

Inside this compact but complex block of metal lies a miniature hydraulic computer. It’s essentially an analog circuit board powered by oil—a network of valves, channels, and solenoids that decide, instantly and flawlessly, how your dozer, excavator, or loader moves, shifts, and transfers power.

Understanding this core component helps you prevent costly downtime, diagnose performance issues early, and protect your transmission investment.

What Is a Transmission Valve Body in Heavy Equipment?

A transmission valve body is a precision-engineered hydraulic control module, typically made from cast aluminum, installed inside the transmission oil pan.

At first glance, it resembles a metal labyrinth cut with precision channels—“hydraulic worm tracks”—that guide high‑pressure transmission fluid to exact points when called upon.

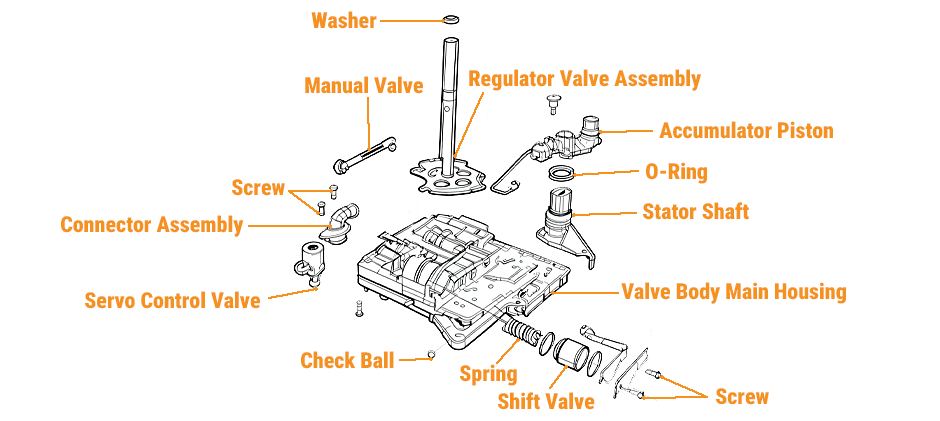

Inside this maze, you’ll find:

- Spool Valves: Sliding cylinders that open and close internal passages to control oil flow.

- Check Balls: Small one‑way valves that keep hydraulic flow moving in the right direction.

- Solenoids: Electrically actuated valves that convert digital commands into analog oil pressure changes.

You can think of the valve body as a liquid‑logic computer.

Each passageway functions like a line on a circuit board, fluid replacing electrons. Pressure, rather than voltage, carries the signal. It’s a live example of the hydraulic analogy in action—the principle that hydraulic circuits behave like electronic ones. Every “bit” of movement inside your machine runs through this self-contained fluid system.

How Does a Transmission Body Work

Here’s what happens every time your machine shifts gears:

- Sensor Inputs: The Transmission Control Module (TCM) and Engine Control Unit (ECU) collect data—throttle position, load, speed, and temperature.

- Electronic Command: The TCM decides to change gears and sends precise electrical signals to solenoids in the valve body. A failure in this system can trigger warnings like “Engine Power Reduced“.

- Hydraulic Execution: Activated solenoids redirect oil through specific channels, applying or releasing internal clutches via hydraulic pressure.

- Mechanical Response: The clutch pack for the new gear engages while the previous one releases—all within milliseconds—ensuring seamless power delivery across different types of transmissions.

It’s a perfect union of electronics, mechanics, and hydraulics—where software meets fluid power.

Why The Valve Body Is Like a Hydraulic Circuit Board

Much like an electronic control board, a valve body:

- Processes input signals (pressure, flow, electrical current).

- Routes logic paths through internal channels.

- Controls output actions (gear changes, clutch engagement).

This makes it a hydraulic analog computer, executing flow-based “decisions” without traditional processors.

Think of each valve as a transistor, each fluid passage as a wire, and each solenoid as an amplifier—the final output being mechanical motion rather than electric current.

Types of Transmission Valve Bodies

| Type | Technology | Common Use | Key Traits |

|---|---|---|---|

| Hydraulic Valve Bodies | Purely pressure-based | Older or legacy off-road equipment | Rugged, reliable, but lacks adaptive intelligence |

| Electro‑Hydraulic Valve Bodies | Combines fluid circuits with electronic solenoids | Modern Tier‑4 machines | Adaptive shift logic, diagnostics, and fuel‑efficient |

Modern systems use the electro‑hydraulic type, enabling sophisticated shift control customized to operator demand, load, and terrain.

Common Signs of a Failing Valve Body

Ignoring early warning signs can ruin an entire transmission. Watch for:

- Delayed or Harsh Shifts: A jolt or lag in gear changes signals pressure imbalance or sticky valves.

- Hunting or Gear Confusion: The TCM compensates for bad valve logic, causing erratic shifting.

- Flare or Slip on Upshifts: Engine revs rise between gears — fluid isn’t reaching the clutch packs correctly.

- Transmission Overheating: Blocked passages prevent cooling circuit flow.

- Torque Converter Lock-Up Problems: Caused by malfunctioning control solenoids. This can be an expensive fix, so understanding the torque converter replacement cost is important.

- Active Fault Codes: Errors such as “Shift Solenoid Performance” or “Pressure Control Circuit Low” almost always trace to valve body or solenoid issues.

Root Causes of Valve Body Failure in Harsh Work Environments

Heavy equipment faces extreme stress. The top culprits include:

- Contaminated Fluid: Tiny debris or metal shavings clog control ports, stick valves.

- Heat Degradation: Overheated ATF thickens and loses lubricity, forming varnish.

- Electrical Solenoid Burnout: Wear or coil damage from voltage spikes or heat.

- Internal Wear: Aluminum valve bores erode over time, causing internal pressure leaks.

- Low Maintenance Intervals: Ignoring scheduled fluid and filter changes accelerates all of the above.

Can You Operate with a Faulty Valve Body?

In short, don’t.

Running a machine with valve body issues means operating with false hydraulic logic. A stuck valve or leaky passage can cause uncontrolled slippage, clutch burn, or breaker‑band failure. Every minute you continue operating, you risk a complete transmission rebuild costing tens of thousands.

Replace vs. Rebuild: The Smart Fleet Decision

| Option | Downtime | Cost Efficiency | Reliability |

|---|---|---|---|

| Rebuild | Long (1–2 days minimum) | High labor cost | Risk of latent flaws |

| Replace / Remanufacture | Short (a few hours install) | Lower total cost | Tested and warrantied |

Modern electro‑hydraulic valve bodies are so intricate that replacement with a professionally remanufactured unit is nearly always the most practical solution.

At FridayParts, each valve body is precision tested to OEM specs, giving operators full confidence and reducing cost-per-hour of operation.

Maintaining a Healthy Transmission Valve Body

- Use OEM‑grade fluids and follow service intervals.

- Install magnetic filters to capture micro‑debris.

- Avoid overheating — monitor transmission fluid temperature.

- Run diagnostic scans regularly to identify early pressure or shift solenoid irregularities.

Why the Hydraulic Analogy Matters

Understanding the hydraulic analogy helps operators visualize how every circuit in the valve body works like a fluid‑based logic board.

Just as an electrical circuit uses voltage and current to move electrons through components, the valve body uses pressure and flow to move oil through mechanical valves and passages.

Each spool and ball acts as a hydraulic “gate”, and the entire unit behaves as a programmable analog computer powered by transmission fluid—controlling clutch timing, torque distribution, and shift smoothness.

Partner with FridayParts for Reliable Transmission Solutions

A properly functioning valve body keeps your machine productive, efficient, and safe.

Whether you need replacement solenoids, full assemblies, or diagnostic support, FridayParts specializes in OEM‑quality off‑road powertrain components, shipped fast worldwide.

Visit FridayParts.com to find tested transmission valve bodies, solenoids, and rebuild kits for your model — so your machinery shifts strongly and works longer.