When we’re planning a heavy lift, the boom style is often the first “make or break” decision. A lattice boom can unlock longer reach and higher capacity, but it also changes how we mobilize, assemble, and maintain the crane. In this article, we’ll answer the practical question—which two cranes typically use a lattice boom—and we’ll compare them in a way that helps us choose the right machine for real jobsites.

What is a Lattice Boom Is?

A lattice boom is a boom made from high-strength steel members arranged as a truss (triangular patterns). Instead of a solid box section, it’s an open structure that delivers high stiffness and strength with less dead weight than a similarly strong “solid” boom.

That design matters because every pound of boom is “load” the crane must carry. Reducing boom weight helps the crane keep more of its rated capacity available for the hook load at longer radii.

Typical lattice boom characteristics

- Truss construction (triangles) for rigidity

- Modular sections are pinned or bolted together to build the boom length

- Strong strength-to-weight ratio compared with many solid booms

- Often paired with jibs and heavy-lift configurations (depending on crane type)

Where lattice booms shine

- Long reach picks (large radius lifts)

- Heavy lifts where the boom’s self-weight becomes a limiting factor

- Projects where the crane will stay on site long enough to justify assembly time (often true for crawler work)

Which Two Cranes Typically Use a Lattice Boom?

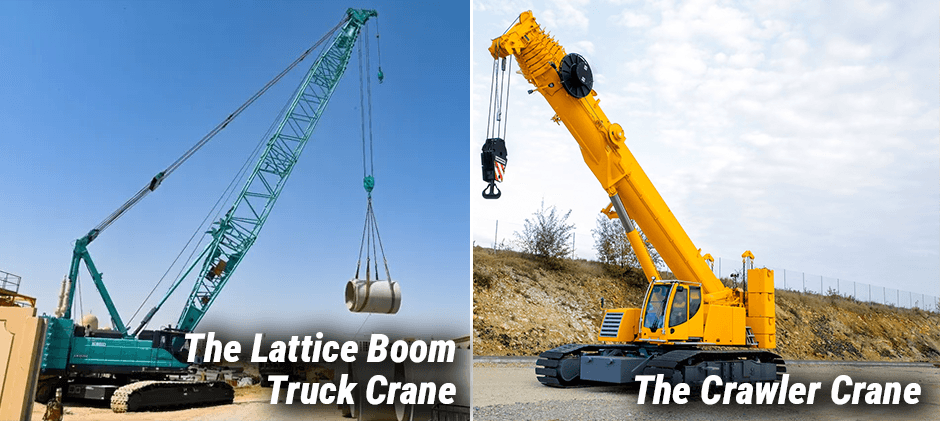

In everyday heavy construction and industrial lifting, the two crane types most commonly associated with lattice booms are:

- Crawler cranes (lattice boom crawler cranes)

- Lattice boom truck cranes (truck-mounted cranes using a lattice boom rather than a telescopic boom)

These are the “typical two” because both platforms can support the structural and operational demands of a lattice boom, just in very different ways.

Before we compare them head-to-head, let’s examine each one from a jobsite perspective.

The Crawler Crane: Lattice Boom’s Most Common Partner

A crawler crane is a mobile crane mounted on tracks. In lattice boom form, it’s often selected when high capacity, stability, and controlled movement around a site are needed—especially on softer or uneven ground, where tires and outriggers would be less forgiving.

Why do crawler cranes commonly use lattice booms?

- Stability comes from the undercarriage and counterweight, not just outriggers. Tracks spread the load over a larger footprint than many wheeled setups.

- Lattice booms can be built long without becoming impractically heavy.

- The crane can “walk” slowly with a load in some planned scenarios (only when permitted by the crane’s load chart and site plan).

Where do we usually see them?

- Bridge and interchange construction

- Heavy industrial maintenance (refineries, plants, large mechanical settings)

- Wind component handling (depending on site access and lift plan)

- Large foundation and civil work where the crane stays for weeks/months

Trade-offs to be honest about

A crawler’s strength is also its drawback:

- Mobilization can require multiple transport loads (boom sections, counterweights, crawlers, accessories).

- Assembly/disassembly takes time, crew, and space.

- Owning or renting a crawler makes most sense when we can keep it utilized, not constantly moving between distant sites.

The Lattice Boom Truck Crane: Road Mobility with Truss Strength

A lattice boom truck crane combines a truck carrier (for travel) with a lattice boom superstructure. We typically choose it when we want more reach/capacity efficiency than a comparable telescopic truck crane, but we still value road mobility and faster relocation compared with a crawler.

Why do truck-mounted cranes use lattice booms?

- The lattice boom provides strong lifting capability without the boom becoming excessively heavy.

- The truck carrier supports faster moves between jobs than a crawler that must be broken down and hauled.

- For contractors doing regional work, the ability to reposition frequently can matter as much as maximum capacity.

Operational realities

Most truck-based cranes still rely on outriggers and need proper ground support (mats, cribbing, and verified soil/ground bearing capacity).

The work area is often tighter (urban/industrial sites), so we must plan:

- swing radius

- tail swing/counterweight clearance

- outrigger footprint

- overhead obstructions and powerline clearance

Crawler Crane vs. Lattice Boom Truck Crane

Both are answers to “Which two cranes typically use a lattice boom?”—but they behave differently in cost, logistics, and risk. Here’s a direct comparison you can use during planning.

Comparison table

How do we decide in practice?

A useful way to think about it:

- If we’re building a job around the crane (large project, long duration), a crawler often wins.

- If we’re fitting the crane into many jobs (moving frequently, varied sites), a lattice boom truck crane often wins.

Key Considerations When Choosing

This is where mistakes get expensive. The right crane isn’t only about “maximum tonnage.” It’s about the load chart at the working radius, the site, and the schedule.

1) Lift requirements (capacity is not just the load weight)

We should confirm:

- Pick weight (including rigging, hook block, headache ball, etc.)

- Working radius (the silent capacity killer)

- Required hook height and boom length

- Whether we need a jib and what that does to the chart

- Wind limitations for the planned configuration

Tip: Two cranes with the same “maximum ton” rating can have very different real-world capacity at your actual radius and boom length.

2) Site conditions and ground support

For both crane types, ground support is non-negotiable. The difference is how the load goes into the ground.

- Crawler cranes distribute load through tracks, but they can still overstress poor ground.

- Truck cranes concentrate load through outriggers, so we often need mats/cribbing and a verified support plan.

3) Mobilization, assembly space, and time

Ask early:

- Do we have room to stage boom sections and counterweights?

- Can the site accept transport deliveries and cranes for assembly support?

- Is the crane staying long enough to justify the assembly time?

4) Safety and control system reliability

Lattice boom work depends heavily on control accuracy and limit protection (for example, limit switches and electrical/hydraulic control components). When uptime matters, sourcing compatible replacement parts quickly is part of the plan—not an afterthought.

Mid-project, many of us end up needing common items like sensors, switches, solenoid coils, valves, filters, or electrical parts. If you’re preparing for maintenance or a turnaround, it helps to keep a reliable supplier bookmarked for crane parts so you can match components faster and reduce downtime.

5) Total cost (not just rental or purchase price)

We get a more accurate budget when we include:

- Mobilization/demobilization and transport

- Assembly/disassembly labor

- Required support equipment (assist cranes, forklifts, rigging gear)

- Consumables and maintenance items

- Schedule risk (weather, access delays, inspection holds)

Maintenance Notes for Lattice Boom Cranes

A lattice boom is rugged, but it has many joints and interfaces. Small problems can become big ones if we ignore them.

Common lattice-boom maintenance checkpoints

- Boom pins, pendants, and connection points (wear, deformation, correct retention)

- Wire ropes (broken wires, corrosion, lubrication, spooling issues)

- Hydraulic system (leaks, filter condition, valve response)

- Electrical controls and switches (limit switches, connectors, water intrusion, harness chafing)

- Hook block and sheaves (bearing condition, groove wear)

If your crew is maintaining multiple machines, a broad inventory matters. FridayParts’ crane category highlights that they carry a wide spread of crane-related parts (engine, electrical, hydraulic, seal kits, and maintenance accessories). When we need to replace worn items or address control issues quickly, going straight to crane parts can be a practical way to narrow options by equipment type and reduce mismatch risk.

FAQs

Which two cranes typically use a lattice boom?

Most commonly, crawler cranes and lattice boom truck cranes. They’re the standard answers because their platforms can support long, modular truss booms used for heavy lifting and extended reach.

Is a lattice boom always stronger than a telescopic boom?

Not “always stronger” in every sense, but a lattice boom often offers an excellent strength-to-weight advantage for long boom lengths. Telescopic booms can be faster to set up and easier to transport, while lattice booms can be better for long-reach and heavy-lift efficiency.

Why does a lattice boom take longer to set up?

Because it’s built from sections that must be staged, pinned, and inspected. That modular design is what gives the boom flexibility and reach, but it increases labor and planning time.

Are crawler cranes always better for rough ground?

Crawler cranes generally handle uneven or softer ground better due to track load distribution, but we still must verify ground bearing capacity and stability. “Tracks” do not eliminate the need for proper ground evaluation.

Final Words

The two crane types that typically use a lattice boom are crawler cranes and lattice boom truck cranes. Crawlers lean toward maximum stability and long-duration heavy lifting, while truck-mounted lattice boom cranes balance strong lifting capability with easier relocation. If we choose based on radius, site support, and mobilization reality—not just headline tonnage—we avoid costly resets and keep the project moving.