A steady glow plug light is a normal part of the pre-heating process on most modern diesel equipment, but a flashing light is a clear warning of a fault. However, not all off-road machines have this indicator; its presence depends on the engine’s age and electronic systems. This guide will help you understand why this light exists, decode what a flashing symbol means, identify the common causes from a failed glow plug to complex engine issues, and provide the knowledge you need to prevent costly downtime.

Key Summary Points

- A STEADY Light is Normal: Upon the inaugural rotation of the ignition key, the glow plug indicator remaining steadily illuminated signifies that the glow plugs are presently engaged in the warming of the engine’s combustion chambers. One ought to await the extinguishment of this indicator prior to initiating the engine.

- A FLASHING Light Signals a Fault: Should the indicator commence flickering or blinking, it no longer pertains to the ordinary preheating sequence. Rather, it is a warning transmitted by the Engine Control Unit (ECU), intimating that it has discerned an irregularity within the glow plug system or its correlated engine management components.

- Common Causes Vary: The issue may be of a trivial nature, such as the failure of a solitary glow plug, or of intricate complexity, encompassing malfunctions of the control module, deterioration of wiring, or even complications within the fuel injection apparatus.

- Do Not Ignore It: To operate machinery whilst the glow plug indicator is flashing is to invite grave consequences.

What Does a Glow Plug Light Symbol Mean?

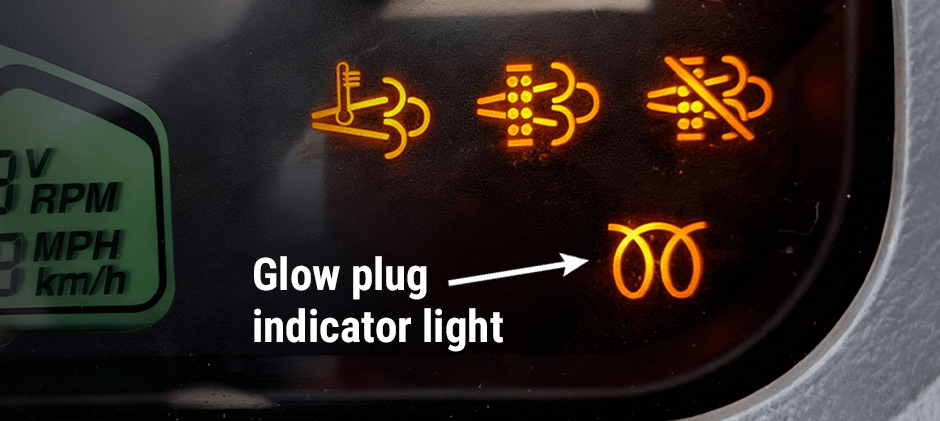

The glow plug light symbol on your dashboard, which looks like a small coiled wire, is a unique and essential feature of any glow plug diesel engine. Unlike gasoline engines, which employ spark plugs to ignite the fuel, diesel engines rely upon the heat engendered by high compression to initiate combustion.

When the engine is in a state of coolness, the metallic structure of the block and cylinder head absorbs this heat, rendering it arduous to attain the requisite temperature for ignition. It is at such a juncture that the glow plugs become indispensable — diminutive heating elements extending into the pre-combustion chamber of each cylinder.

Here’s the normal sequence:

- Turn the ignition key to the “ON” position.

- The ECU supplies electricity to the glow plugs.

- The glow plug light on the instrument panel illuminates, signifying that the glow plug temperature is ascending rapidly to beyond 1,000°F (540°C).

- After several seconds (which might be prolonged under cold weather circumstances), the cylinder temperature becomes sufficiently elevated to ensure reliable combustion.

- The indicator light extinguishes, denoting that you may now commence the engine.

A steady indicator light is a good sign; it indicates that the system operates ordinarily. However, when the indicator begins to flicker, it manifests that some irregularity has emerged within the process.

Why is My Glow Plug Light Flashing?

The flickering glow plug light is the machine’s peculiar manner of communicating certain malfunctions. The ECU persistently supervises the glow plug system, and upon perceiving readings that deviate from the anticipated parameters—such as improper resistance, a short circuit, or an open circuit—it shall initiate the blinking of the indicator. The following are the most frequent causes of such failure, arranged from the elementary to the intricate.

1. One or More Failed Glow Plugs

This stands as the most prevalent cause by far. Glow plugs are consumable components; their lifespan is inherently finite. After thousands of thermal cycles, they may perish in several ways:

- Burnout: The internal heating element becomes fractured, resulting in an open circuit.

- Carbon Fouling: Excessive accumulation of carbon during combustion may insulate the glow plug, rendering it incapable of adequately heating the combustion chamber and thereby altering its resistance.

- Swelling: Overheating may cause the tip of the glow plug to expand; if the tip breaks off, severe damage to the engine may result.

When the Electronic Control Unit (ECU) endeavors to deliver current to a defective glow plug, it detects erroneous electrical feedback and consequently activates the flashing light. Common accompanying symptoms include difficulty in starting, unstable idling during cold starts, and excessive white smoke emitted from the exhaust before engine warm-up.

2. A Faulty Glow Plug Control Module or Relay

The control module serves as the brain of the glow plug system. It receives information from the main ECU (including the engine temperature) and precisely determines the duration of power supply to the glow plugs.

If this module or its associated relay fails, it can lead to several problems:

- No Power to Plugs: The module may fail to send any electricity, leading to a no-start condition in the cold and a flashing light.

- Incorrect Duration: It might keep the glow plugs on for too long, causing them to burn out prematurely, or not long enough, causing hard starts.

- Internal Short: A failure within the module itself will be detected by the ECU and trigger the fault light.

The operating environment of heavy machinery is of extreme severity. Continuous vibration, dust, moisture, and temperature fluctuation are capable of inflicting harm upon the electrical system. The harness linking the control module and the glow plugs is particularly susceptible to impairment.

3. Damaged Wiring or Poor Connections

The operating environment of heavy machinery is of extreme severity. Continuous vibration, dust, moisture, and temperature fluctuation are capable of inflicting harm upon the electrical system. The harness linking the control module and the glow plugs is particularly susceptible to impairment.

- Corrosion: Humidity may induce corrosion upon the connectors of the glow plugs or the module, generating high resistance and thus giving rise to a malfunction.

- Abrasion/Fracture: The wires may rub against engine components, wearing away the insulation layer and resulting in a short circuit. The wires might also suffer rupture due to persistent vibration.

- Loose Connection: Vibrations may loosen the connectors, causing circuit interruption.

The ECU is exceedingly sensitive and capable of perceiving such electrical irregularities, which commonly lead to the flickering of the glow plug indicator.

4. A Broader Engine Management Fault

In numerous modern apparatuses, the glow plug light assumes a dual mission. Its principal function lies in denoting a defect within the glow plug system, yet it may also be summoned by the Engine Control Unit (ECU) to serve as an auxiliary “Check Engine” emblem, betokening other diesel-related predicaments. The flickering of this light might intimate that maladies exist in the following domains:

- Fuel Injectors: Aberrations within the injector circuitry.

- EGR (Exhaust Gas Recirculation) System: The EGR valve has become seized or fallen into disrepair.

- DPF (Diesel Particulate Filter) System: Troubles with DPF regeneration or its sensors.

- Engine Sensors: When vital sensors — such as the coolant temperature sensor or the crankshaft position sensor — descend into failure, the glow plug indicator may be invoked as a general proclamation of engine affliction.

In these cases, the blinking illumination may merely signify deeper causation beneath the surface, demanding the employment of diagnostic scanning instruments to divine the specific fault codes concealed within.

Glow Plug Preventing Tips

Though it is beyond possibility to render the glow plug everlasting, one may, however, adopt certain means to maximize its span of service and avert premature failure.

- Always Follow the Proper Starting Procedure: Never commence the engine before the glow plug indicator extinguishes. This ensures the completion of the preheating ceremony and diminishes the burden upon the starting apparatus.

- Use High-Quality Diesel Fuel: Clean fuel possessing an elevated cetane value enhances combustion efficiency and mitigates the carbon accretion upon the tip of the glow plug.

- Perform Regular Visual Inspections: During routine maintenance, inspect the harness that joins to the glow plugs. Observe whether the connectors display any sign of cracking, abrasion, or corrosion.

- Replace Glow Plugs as a Full Set: Should one glow plug succumb to failure, the others share equal operational hours and thermal cycles. Thus, renewing the whole set at once stands as a prudent precaution, sparing repeated shutdowns and labor expenditure. Acquiring trustworthy aftermarket components renders this a most economical and effective stratagem.

- Address Hard Starting Immediately: If your machinery reveals obstinate starting, do not persist in cranking. Such insistence imposes immense strain upon the battery, the starter, and the glow plugs themselves. Diagnose forthwith the underlying cause.

Glow Plug Light FAQs

Q1: Why shouldn’t I just ignore a flashing glow plug light?

Ignoring the light means ignoring a problem. A simple failed glow plug can make starting difficult, which wears out your battery and starter. If the light indicates a more serious engine management issue, continuing to operate the machine could lead to catastrophic and extremely expensive failures of components like the DPF or fuel system.

Q2: Should I replace all my glow plugs at the same time?

Yes, of course. The wear speed of glow plugs is roughly comparable. Only replacing the damaged glow plug can merely temporarily solve the problem, which almost signifies that you will soon repeat the same operation on another cylinder. Replacing them as a full set can save labor and minimize future downtime to the utmost.

Q3: How often do glow plugs need to be replaced on heavy equipment?

There is no single answer, for its service life heavily depends on the running hours, frequency of start-stop, quality of fuel, and climatic conditions. Generally speaking, it ought to be inspected within major maintenance cycles and replaced every several thousand hours or when starting performance begins to decline.

Keep Your Fleet Firing on All Cylinders

A flashing glow plug light is a crucial indicator of engine health. Understanding potential causes and implementing preventative maintenance measures can help prevent further damage. Glow plugs, as consumable parts, require frequent inspection and replacement. If you’re concerned about replacement costs, consider FridayParts‘ aftermarket parts. As a leading aftermarket parts supplier, we offer both quality and affordability to address your price concerns. We also offer a wide selection of high-quality, durable parts for numerous heavy equipment brands at affordable prices to keep your machine running smoothly.