What Causes Cylinder Head Failure in Your Engine

You’re driving along when suddenly your temperature gauge spikes, or maybe you notice white smoke billowing from your exhaust. These could be signs of cylinder head failure – one of the most expensive engine problems you can face. At FridayParts, we’ve seen countless cases of cracked cylinder heads, and we know how frustrating this can be for equipment owners.

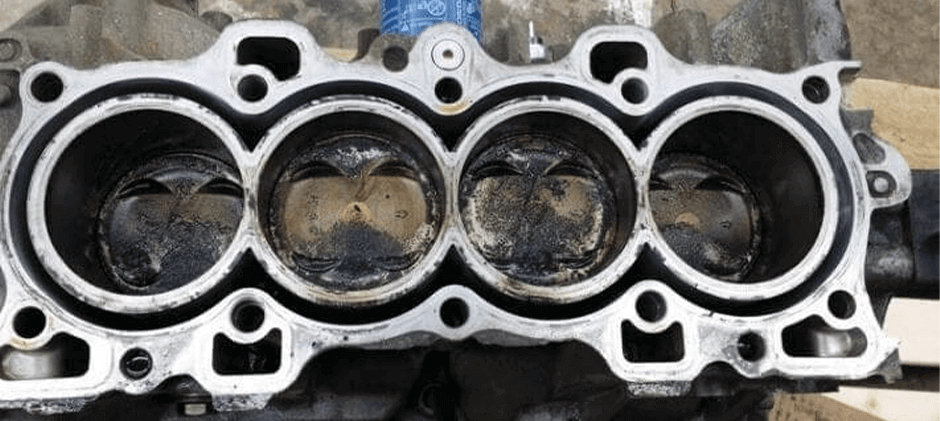

Your cylinder head sits on top of your engine block, sealing the combustion chambers and housing vital components like valves, springs, and often camshafts. When this critical part fails, you’re looking at serious engine trouble. The cylinder head endures extreme temperatures – we’re talking about metal that expands and contracts hundreds of times during every trip you take. Add in the pressure from combustion (up to 1,000 PSI in diesel engines), and you’ve got a recipe for potential cylinder head failure if something goes wrong.

Most cylinder head problems don’t happen overnight. They develop gradually due to overheating, poor maintenance, or manufacturing defects. The good news? If you catch the warning signs early, you might save yourself from a complete engine rebuild.

Common Signs Your Cylinder Head Is Cracked

When your cylinder head starts failing, your engine will definitely let you know something’s wrong. The most obvious sign is the coolant mysteriously disappearing without any visible leaks. Where’s it going? Right into your combustion chambers or oil system through tiny cracks in the head.

You might also notice milky oil on your dipstick – that’s coolant mixing with engine oil, creating a chocolate milk-like substance that can’t lubricate properly. Check your oil cap too; if you see a creamy residue there, you’ve likely got cylinder head failure brewing. White exhaust smoke is another dead giveaway, especially if it smells sweet like antifreeze. That’s coolant burning in your cylinders, and it won’t stop until you fix the cracked head.

Engine misfires and rough idling often accompany cylinder head problems. When coolant leaks into a cylinder, it prevents proper combustion, causing that cylinder to misfire. You’ll feel the engine shaking, especially at idle. Some folks also report a bubbling sound from the radiator when the engine’s running – that’s combustion gases escaping through head cracks into the cooling system.

Why Cylinder Heads Crack and Fail?

Overheating ranks as the number one killer of cylinder heads. When your engine runs too hot, the aluminum or cast iron head warps and cracks under thermal stress. Maybe your radiator was low on coolant, your thermostat stuck closed, or your water pump failed – any cooling system problem can trigger catastrophic cylinder head failure.

Poor maintenance habits accelerate head problems too. Using the wrong coolant mixture, skipping coolant changes, or running with old, contaminated oil puts extra stress on your cylinder head. We see this all the time at FridayParts – folks trying to save a few bucks on the maintenance end up with thousand-dollar repair bills. The thermal cycling from repeated cold starts without proper warm-up time also contributes to premature head failure.

Manufacturing defects, though less common, can cause early cylinder head failure. Some engine models have known weak spots where cracks typically develop. Improper installation plays a role too – if your head bolts weren’t torqued correctly during assembly or a previous repair, uneven pressure distribution leads to warping and eventual cracking. Age and high mileage naturally wear down any cylinder head, making older engines more prone to this type of failure.

Cylinder Head Repair Costs You Should Expect

Let’s talk money – because cylinder head failure hits your wallet hard. For most vehicles, you’re looking at 2,000to2,000 to 2,000to4,000 for professional cylinder head replacement. Diesel engines and heavy equipment? Those bills can easily double. The cylinder head itself costs anywhere from 500to500 to 500to2,000, depending on your engine type and whether you choose OEM or aftermarket parts.

Labor makes up the biggest chunk of your repair bill. Replacing a cylinder head means dismantling half your engine – we’re talking 8 to 20 hours of labor at $100-150 per hour. Your mechanic needs to drain fluids, remove the intake and exhaust manifolds, disconnect dozens of sensors and hoses, then carefully extract the old head without damaging the block. Installation reverses this process, plus they’ll need to adjust valve clearances and timing.

| Repair Option | Cost Range | Time Required |

|---|---|---|

| Head Gasket Only | $1,000-2,000 | 4-8 hours |

| Cylinder Head Repair | $500-1,500 | 2-5 days |

| Complete Head Replacement | $2,000-4,000 | 1-3 days |

| Engine Replacement | $3,000-7,000 | 2-5 days |

Sometimes you can repair a cracked cylinder head through welding or pinning, which costs less than replacement. However, this only works for minor cracks, and not all shops offer this service. Many mechanics recommend replacement over repair for reliability.

Prevention Tips to Avoid Cylinder Head Problems

You can prevent most cylinder head failures with basic maintenance. Keep your cooling system in top shape – that means checking coolant levels weekly, flushing the system every two years, and replacing thermostats and water pumps at recommended intervals. Never ignore overheating; pull over immediately if your temperature gauge climbs into the red zone.

Use quality coolant mixed to manufacturer specifications. A 50/50 mix of antifreeze and distilled water works for most applications, but check your owner’s manual. Wrong coolant concentration causes corrosion and reduces heat transfer, both contributing to cylinder head failure. Replace your radiator cap when it can’t hold pressure – a bad cap lets coolant boil at lower temperatures, creating hot spots that crack heads.

Regular oil changes protect your cylinder head too. Clean oil carries heat away from the head and lubricates valve train components housed within it. Dirty oil forms deposits that insulate parts, causing localized overheating. We recommend synthetic oil for better temperature resistance, especially if you work your engine hard. Also, warm up your engine gradually in cold weather – thermal shock from rapid temperature changes causes cylinder head stress fractures over time.

When to Replace vs Repair Your Cracked Head

Deciding between repair and replacement depends on crack severity and location. Small external cracks away from combustion chambers might be weldable, saving you thousands. But cracks between valve seats, into water jackets, or across multiple areas usually mean replacement time. Your mechanic can perform pressure tests and crack detection to assess damage accurately.

Consider your engine’s overall condition before investing in cylinder head work. If you’ve got 200,000 miles on the clock with worn rings and bearings, fixing just the head might not make economic sense. Sometimes, a used or remanufactured engine costs barely more than extensive head repairs, plus you get renewed reliability throughout.

At FridayParts, we often see customers struggle with this decision. Our advice? Get multiple opinions and detailed estimates. Ask about warranty coverage – reputable shops guarantee cylinder head repairs for at least 12 months. Factor in your equipment’s value and how long you plan to keep it. For newer machines or those critical to your business, investing in proper cylinder head repair or replacement usually pays off through continued reliable service.

FAQs

How long can you drive with a cracked cylinder head?

You shouldn’t drive at all with a confirmed cracked cylinder head. Even short trips cause severe engine damage as coolant enters cylinders, washing away oil and scoring cylinder walls. Continuing to run damages pistons, bearings, and potentially the entire engine block, turning a 3,000cylinderheadrepairintoa3,000 cylinder head repair into a 3,000cylinderheadrepairintoa7,000 engine replacement.

Can a cylinder head crack without overheating?

Yes, cylinder heads can crack from manufacturing defects, improper installation torque, or metal fatigue after years of thermal cycling. Some engines have design weaknesses where heads crack prematurely. Freezing coolant due to insufficient antifreeze concentration also cracks heads without overheating involvement.

What’s the difference between a blown head gasket and a cracked cylinder head?

A blown head gasket is just the seal between your cylinder head and engine block failing, while a cracked head means the actual metal casting has fractured. Head gasket replacement costs less and takes less time. Both cause similar symptoms like coolant loss and white exhaust smoke, but cracked heads require complete replacement or specialized welding repairs.

Will cylinder head sealers actually fix cracks?

Liquid sealers work temporarily for tiny cracks or porosity issues, buying you time to arrange proper repairs. They won’t fix significant cracks or warped heads. These products can clog radiators and heater cores if overused. Consider sealers as emergency bandaids, not permanent cylinder head failure solutions.

How do mechanics test for cylinder head cracks?

Mechanics use several methods to detect cylinder head failure: pressure testing reveals external cracks, dye penetrant testing shows surface cracks, and magnafluxing finds hidden cracks in iron heads. They’ll also check for combustion gases in your coolant using chemical tests, confirming internal cylinder head problems.