When the wiper blade of your equipment begins to leave traces on the glass or produce that kind of sharp sound, it is already the first indication that replacement is necessary. Wiper blades, although seeming to be small components, are indeed those indispensable parts which operators frequently neglect; however, they are exactly the reason your visibility can remain clear under rain, fog, or even flying dust, ensuring that precise control may be continuously maintained. In case you feel uncertain about how to select the suitable type or proper size of wiper blades for your machine, this guide will explain everything within one single place, so that you no longer need to search here and there among scattered information.

Different Types of Wiper Blades

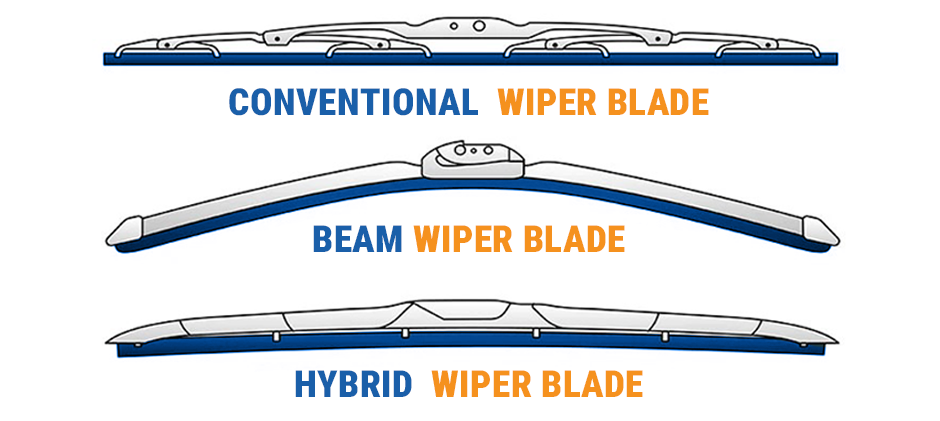

In the world of off-road equipment, wiper blades fall into three main categories: conventional, beam, and hybrid. Each offers distinct performance characteristics depending on working environments and machine design.

1. Conventional Wiper Blade (Frame Type)

Structure: A rigid metal framework holding a rubber strip, providing distributed pressure along flat or slightly curved glass.

Applications: Common in older or compact off-road machines such as small excavators, loaders, and dozers.

Pro:

- Simple and rugged construction suitable for vibration and dirt exposure.

- Easy to replace or maintain.

- Wide compatibility across various machines.

Cons:

- Limited number of pressure points, sometimes missing tight curvature areas.

- Metal joints can corrode under heavy moisture or chemical exposure.

Usage Share: Around 60% of off-road machines still rely on this type for everyday performance and maintenance simplicity.

2. Beam Wiper Blade (Flat Type)

Structure: A curved steel or composite spine enclosed in a one-piece aerodynamic rubber design, ensuring uniform contact along the entire windshield.

Applications: Found in new-generation excavators, dump trucks, and loaders with panoramic or curved cab glass.

Pro:

- Excellent glass contact and smooth wiping under high wind resistance.

- Less prone to clogging; perfect for dusty construction or mining conditions.

- Consistent performance even in heavy rainfall.

Cons:

- Requires specific wiper arm connections (hook, bayonet, or bolt-on).

- Slightly heavier than conventional types.

Usage Share: Approximately 25% of modern construction equipment utilizes beam types for enhanced visibility and reduced maintenance downtime.

3. Hybrid Wiper Blade

Structure: A fusion of a metal support frame with a curved, enclosed shell for improved aerodynamics.

Applications: Used in high-end tractors, forestry machines, and large loaders working in varied temperatures.

Pro:

- Durable under extreme temperature changes and dust.

- Combines flexibility with resistance to mechanical stress.

- Prefers rugged use where machines operate long hours in mud or snow.

Cons:

- Slightly heavier; not necessary for every application.

Usage Share: Roughly 15%, mostly for operators seeking enhanced endurance and all-weather reliability.

What Type of Wiper Blades Do You Need?

Your equipment environment defines the best wiper blade choice.

- Dry, Dusty Construction Sites: Opt for Hybrid Blades with sealed frames to resist particle buildup.

- Heavy Rain, Fog, or Snow Locations: Choose Beam Blades with continuous curve pressure for even wiping.

- Older Machinery: Conventional Blades are ideal—robust, universally compatible, and easy to replace.

- Machines with Steep or Vertical Glass: Use blades with flexible rubber edges to maintain consistent contact.

Tips: When upgrading, it’s essential to choose wiper blades that meet or exceed original equipment (OEM) specifications. High-quality aftermarket parts are a great option — they’re engineered to the same standards, often with improved materials or design updates. The price is more than half that of original parts, and timely delivery is the choice of most car owners.

How to Check What Size Blades You Need?

Choosing the proper wiper blade size ensures every inch of your windshield stays clear and within the arm’s motion range. Size matters more than you might think: a blade that’s too short can leave dust lines, while one that’s too long may collide with the frame or another blade.

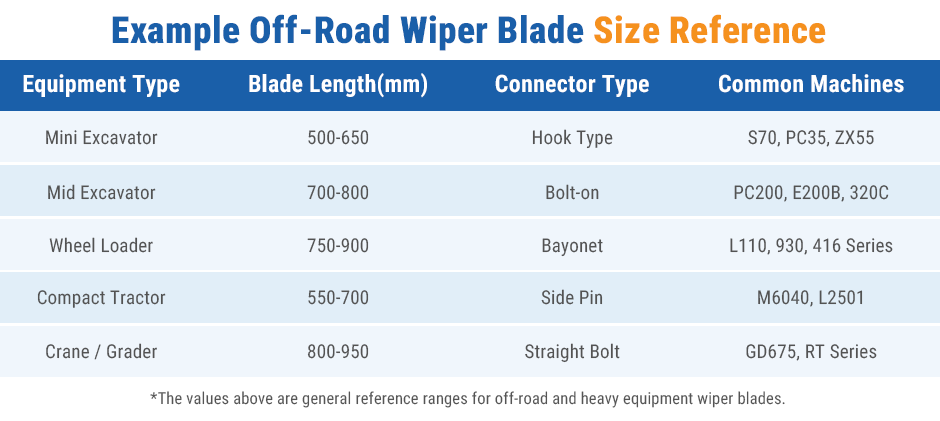

How to find your correct size:

- Check the operator’s manual — many off-road machines specify blade lengths and attachment types.

- Measure your existing blade — measure only the rubber edge, not the arm.

- Use a wiper blade size chart — most manufacturers categorize sizes by machine model or chassis code.

- Match attachment types — ensure your new blade fits your arm’s connector style (hook, bolt-on, bayonet, side pin).

Why Does Wiper Blade Size Matter?

A wiper blade’s efficiency depends entirely on the contact area it makes with the windshield. Too small, and you lose part of your field of vision; too large, and the blades may interfere with each other or cause stress on the wiper motor.

Proper size ensures:

- Full glass coverage for maximum visibility.

- Stable wiping pressure, even under cabin vibration.

- Smooth motion that doesn’t overload the motor or scratch the glass.

Think of it this way—the wrong-sized wiper can reduce your operator’s line of sight as much as fogged glass would. Confirming exact sizing eliminates this risk before installation.

How Often Should They Be Replaced?

Off-road operating conditions accelerate blade wear. Mud, oil mist, and coarse particles lodge in the rubber, reducing flexibility and cutting efficiency. Even when not in constant use, ultraviolet light and cabin heat can harden wiper material.

General replacement recommendation:

- Replace every 6 to 12 months under heavy-duty operation.

- Inspect monthly for cracks, uneven wiping, or streaking.

- Immediately replace if rattling or chatter appears when wiping.

Indicators You Need New Wiper Blades

- Streaks or smears: The rubber edge is worn or contaminated.

- Chattering noises: Loss of flexibility or bent frame.

- Uneven cleaning: Pressure not distributed uniformly.

- Cracking or fraying: Exposure to oil or UV has degraded the material.

Routine maintenance prevents minor issues from evolving into unsafe visibility conditions during critical operations.

Where to Find Reliable Wiper Blades?

Off-road professionals often face downtime caused by small part failures, like wipers. To avoid this, you need blades proven to handle mud, vibration, and wind stress.

FridayParts Wiper Blade offers:

- Blades and assemblies compatible with CAT, Bobcat, Komatsu, Hitachi, Volvo, and more.

- High-quality materials meeting OEM standards.

- Rich inventory for excavators, loaders, cranes, graders, and tractors.

- Components built for easy installation and dependable performance.

Our wiper blades maintain clear visibility through heavy rain, sand spray, or cold conditions, helping operators work safely without downtime.

Maintenance Tips for Extended Wiper Life

- Clean the wiper edge regularly with a damp cloth to remove dust and oil.

- Keep the windshield clean—mud deposits shorten rubber lifespan.

- Engage wipers only on a wet surface, never on dry glass.

- Inspect the arm tension—loose arms reduce wiping pressure.

- Store machinery under cover when not in use to avoid UV degradation.

These simple steps can double your blade’s working life.

Clear Vision Means Productive Operation

In off-road environments, visibility equals control. The correct wiper blade—chosen by type and size—keeps operators safe, efficient, and compliant with safety standards. Your machine might power through rock and mud, but it still depends on clear vision to do the job right. Make that vision last with the right wiper blades.