Air conditioning and heating systems consist of several important components that work together. Ensure the normal operation of the system and keep the operating cabin comfortable all year round. Therefore, the state of all components is critical. Once a blower motor has problems, it often directly affects the cooling or heating effect. So what are bad blower motor symptoms? In the following section, we will briefly talk about common fault performance and judgment ways.

How Does a Blower Motor Work?

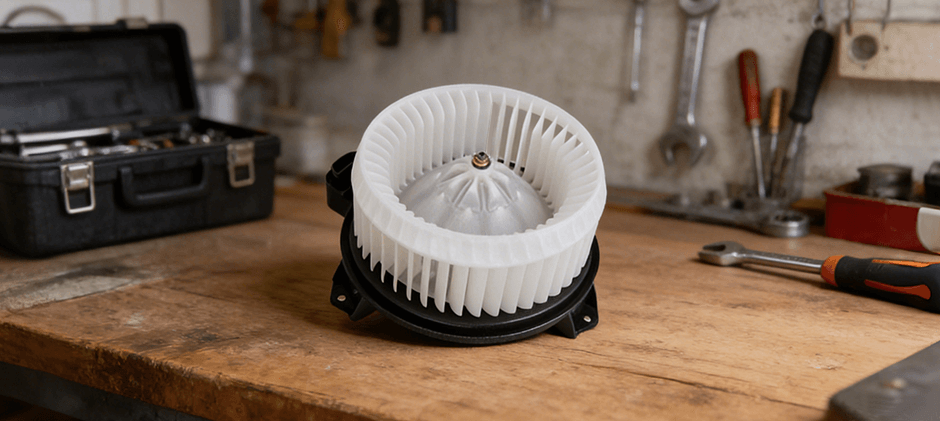

The blower motor can be thought of as the “power source” for the HVAC system. It has a simple structure and consists mainly of a small motor and a fan shaped like a hamster wheel, often called a fan cage.

When you turn on the heating or air conditioning and adjust the air volume, the motor will be powered on and start turning. The fan is for drawing in outside air or circulating air inside the cab. The air is then heated through a heater core or cooled through an evaporator. The treated air is finally blown from the air outlet into the operator’s cabin. If the blower motor is broken, air cannot flow. The heating and cooling systems naturally don’t work properly either.

Common Bad Blower Motor Symptoms

A bad blower motor almost never dies without warning. It usually gives you hints that something’s wrong. Watching for these signs of a faulty blower motor can help you fix the problem before the whole system craps out—super important when the weather’s really extreme.

Weak or No Airflow from Vents

You turn the fan on. Maybe you hear a soft hum. But almost no air comes out—or none at all. That means the blower motor isn’t working right. The motor might struggle to spin. It could be worn out inside or have an electrical glitch. So it can’t push enough air through. Heavy equipment works in dirty, dusty spots. Dirt and gunk can clog the fan cage, too. That blocks airflow—even if the motor is trying to spin.

The Blower Only Works on Certain Speeds

Ever notice the fan only runs when you crank it to max? That’s a dead giveaway that the resistor is shot (or the blower motor control module on newer machines). The blower motor resistor is what controls the motor’s speed. For every lower setting, electricity runs through a different resistor to slow the motor down. But the highest setting usually skips the resistor entirely, sending full power straight to the motor. When the resistor burns out, the lower fan speeds stop working. Only high speed will run. The motor itself might still be fine. But this is a dead giveaway that something’s wrong with the blower motor circuit.

Unusual Noises Are Coming from the Dashboard

Your cab’s HVAC system should hum nicely and steadily. If new, weird noises pop up when the fan’s on, it’s time to take a look. These sounds tell you exactly what’s wrong:

- Rattling or slapping: Leaves, twigs, or clumps of dirt probably got sucked into the blower housing. They’re hitting the spinning fan cage.

- Squealing or grinding: These high-pitched sounds almost always mean the motor’s bearings are worn out. Heavy equipment vibrates a lot and runs for hours straight. Bearings wear down fast because of that. A grinding noise is a big warning—the motor’s about to seize up completely.

Don’t brush off these sounds. Gunk can crack the plastic fan blades. A failing motor will burn out. Fixing the noise early can save you from a way more expensive repair later.

Smoke or a Burning Smell from the Vents

If you see smoke or smell burning plastic or electronics coming out of the vents, that’s a serious electrical problem. It could be a seized motor pulling way too much electricity, which overheats the wires and melts their plastic coating. Or it might be a short circuit in the motor or its wiring.

If this happens, turn off the HVAC system immediately. If it’s safe, shut down the machine too. This is a fire risk—get the system inspected and fixed before you use it again. Ignoring it could damage other parts of the circuit, making the blower motor replacement way more expensive.

An operator’s comfort directly affects their productivity and safety. A broken HVAC system—usually caused by a bad blower motor—isn’t just a hassle. It can be dangerous, leading to heat exhaustion and loss of focus on the job site.

The Causes Of Bad Blower Motor Symptoms

Those symptoms we talked about don’t just pop up out of the blue. They almost always come from one of three main issues. And the tough conditions of off-road work make most of these problems way worse.

Electrical Problems

The blower motor system runs on a circuit with fuses, relays, wires, and a resistor pack. Heavy equipment shakes nonstop. That vibration can make wires wear through their plastic coating. It can also loosen up connections. Corrosion on electrical plugs is super common, too. A blown fuse can shut the motor down cold. A bad resistor causes those speed issues we mentioned earlier. When you need to test a blower motor, checking for power and ground is the first step to figuring out these electrical glitches.

Mechanical Blockages and Debris

Off-road machines work in places full of dust, dirt, leaves, and other junk. The HVAC system’s air intake sucks all that junk right into the blower motor housing. It can jam the fan. Make it wobble and rattle. And eventually overwork the motor until it burns out for good.

Normal Wear and Tear

Let’s face it—a blower motor is just an electric motor with moving parts. Inside parts like brushes and bearings wear out over time. Heavy equipment often runs for thousands of hours. Sometimes the fan runs nonstop. So it’s totally normal for the blower motor to wear out eventually. You’ll just need to replace it.

What Is The Lifespan Of a Blower Motor?

Blower motors for heavy equipment are tough, but they’re still wear-and-tear parts. There’s no set lifespan or hour limit for them. It mostly depends on where and how you use the machine. Take a quarry for example—all that dust means the blower motor is way more likely to act up than if you’re working in a clean area. On top of that, these motors take nonstop vibration, dust, and hours of running day in and day out. So replacing a blower motor is pretty common as the equipment ages. Blower motor replacement cost can vary depending on the brand and model. Changing your cab air filter regularly helps a lot. It keeps dust and junk from getting sucked into the fan—and that’ll make your blower motor last longer.

Summary

Symptoms of a blower motor failure indicate that the HVAC system is faulty or damaged. At this time, immediate measures need to be taken to restore cab temperature control. The measure can be repair or replacement. Depending on the type of fault, you can choose to have it repaired.

The blower motors available from FridayParts are compatible with a variety of heavy equipment brands, helping you get your equipment back up and running faster and with less hassle. If you plan to do the repair yourself, you can also refer to the blower motor fault troubleshooting steps we provide.