Ever stood in the aisle feeling completely lost? You’re not alone. With dozens of solenoid valve types staring back at you, picking the right one feels like rocket science. But here’s the thing – once you know what each type does, choosing becomes dead simple.

At FridayParts, we’ve helped thousands of customers pick the perfect solenoid valve for their needs. Whether you’re fixing industrial equipment, building an irrigation system, or working on your car, we’ll help you understand exactly which valve type gets the job done.

What Makes Solenoid Valves Different from Regular Valves?

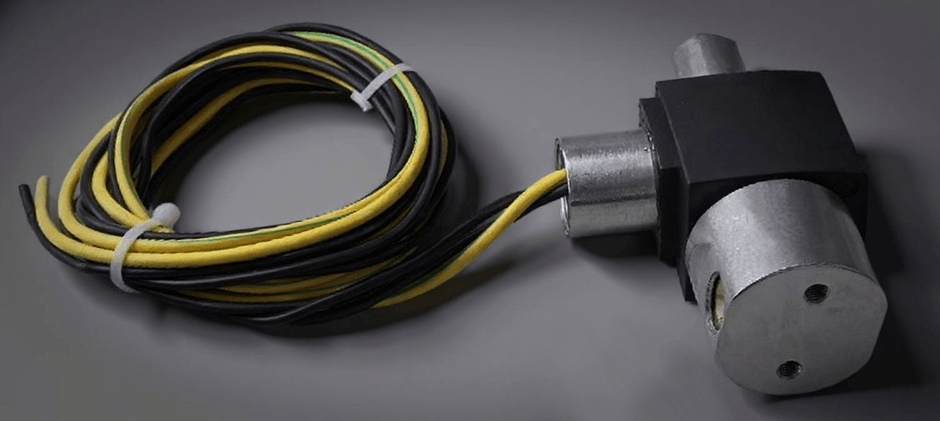

Before diving into specific types, let’s clear up what makes solenoid valves special. Unlike manual valves, which you turn by hand, solenoid valves use electricity to do the work. When you apply power, an electromagnetic coil creates a magnetic field that moves a plunger or armature. This movement opens or closes the valve – no manual effort needed.

Think of it like your garage door opener. Push a button, and electricity does all the heavy lifting. Solenoid valves work the same way – send an electrical signal, and they open or close automatically.

This automation makes them perfect for systems that need remote control or automatic operation.

The beauty of solenoid valves? They work fast, typically opening or closing in milliseconds. They’re also reliable, with some lasting millions of cycles. No wonder they’re everywhere – from your washing machine to massive industrial plants.

2-Way Solenoid Valves

Let’s start with the most common type – 2-way solenoid valves. These valves have two ports: one inlet and one outlet. They do one simple job: start or stop the flow. Think of them as an on/off switch for liquids or gases.

You’ll find 2-way valves everywhere because they’re straightforward and reliable. Your home’s automatic sprinkler system? Probably uses 2-way valves to turn water zones on and off. The ice maker in your refrigerator? Yep, another 2-way valve controlling water flow to the ice tray.

When to choose 2-way valves: Pick these when you need basic on/off control. They’re perfect for filling tanks, controlling pneumatic cylinders, or anywhere you need to start and stop flow. They’re usually the cheapest option, too, which makes them great for simple applications. Just remember – they can’t mix or divert flow. If you need anything fancier than stop/go, keep reading.

3-Way Solenoid Valves

Now we’re getting more sophisticated. 3-way solenoid valves have three ports and can direct flow between them. They’re like a Y-intersection for your fluids – flow can go one way or the other, but not both simultaneously.

These valves typically work in two configurations. In one setup, they mix two inputs into one output. Imagine blending hot and cold water – a 3-way valve can control which source flows to your shower head. In the other setup, they divert one input between two outputs, like sending compressed air to either extend or retract a pneumatic cylinder.

Real-world example: Your car’s heater control valve is often a 3-way type. It either sends hot coolant through the heater core (heat on) or bypasses it back to the engine (heat off). This single valve replaces what would otherwise need two separate 2-way valves, saving space and cost.

The extra port makes these valves incredibly versatile. They’re the go-to choice for controlling double-acting cylinders, managing exhaust functions, or any application needing flow diversion.

Direct Acting vs. Pilot Operated Valves

Here’s where people get confused, but the concept is pretty simple. Solenoid valves use two different methods to open and close: direct acting and pilot-operated.

Direct-acting valves are the straightforward ones. The solenoid coil directly pulls the valve open against spring pressure. When you apply power, the magnetic force lifts the plunger, opening the valve. Cut the power, and the spring slams it shut. These valves work from zero pressure differential, making them perfect for vacuum applications or systems with varying pressures.

Pilot-operated valves are clever. They use the system’s pressure to help open the valve. A small pilot orifice, controlled by the solenoid, releases pressure from above the main diaphragm. System pressure then pushes the diaphragm up, opening the main valve. It’s like using hydraulic power steering – a small input controls a much larger force.

Which type do you need? Direct acting valves work anywhere, but use more power and typically max out around 1-inch size. Pilot-operated valves handle higher flows and pressures with less power, but they need a minimum pressure differential to operate (usually 0.5 PSI or more). No pressure? They won’t open.

Normally Closed vs. Normally Open Valves

This distinction is super easy but matters for your application. It’s all about what the valve does when there’s no power applied.

Normally closed (NC) valves stay shut when the power’s off. Apply electricity, and they open. These are by far the most common type because they fail safe – if you lose power, they stop flow. Your dishwasher’s water inlet valve? Normally closed. Power failure means no flooding.

Normally open (NO) valves do the opposite. They stay open without power and close when energized. These are perfect for safety applications where you need flow during power failures. Emergency cooling systems often use NO valves – if the power fails, cooling continues.

Here’s a quick way to remember: NC valves need the power to flow, NO valves need the power to stop. Choose based on what’s safer for your system during power loss. When in doubt, NC is usually the safer bet.

Proportional Solenoid Valves

While most solenoid valves are simple on/off devices, proportional valves offer precise flow control. Instead of fully open or closed, they can hold any position in between. Think of them as a dimmer switch versus a regular light switch.

These valves use sophisticated electronics to vary the current to the solenoid coil. More current means more magnetic force, which moves the valve further open. By controlling the current, you control exactly how much flow passes through. Some proportional valves are so precise that they can maintain flow rates within 1% accuracy.

Where they shine: Any application needing precise control loves proportional valves. Paint spraying systems use them to maintain exact flow rates. HVAC systems use them for precise temperature control. Medical equipment relies on them for accurate gas mixing. Yes, they cost more than on/off valves, but the control they offer is worth it for many applications.

The downside? They need special controllers and are more complex to set up. But if your process needs fine control, proportional valves deliver results that simple on/off valves can’t match.

4 Special-Purpose Solenoid Valve Types

Beyond the common types, there’s a whole world of specialized solenoid valves designed for specific jobs. Let’s look at some you might encounter:

Latching solenoid valves are energy savers. Send a pulse to open, another to close, and they stay in position without continuous power. Perfect for battery-powered systems or anywhere energy

efficiency matters. Garden irrigation controllers love these because they only use power when changing states.

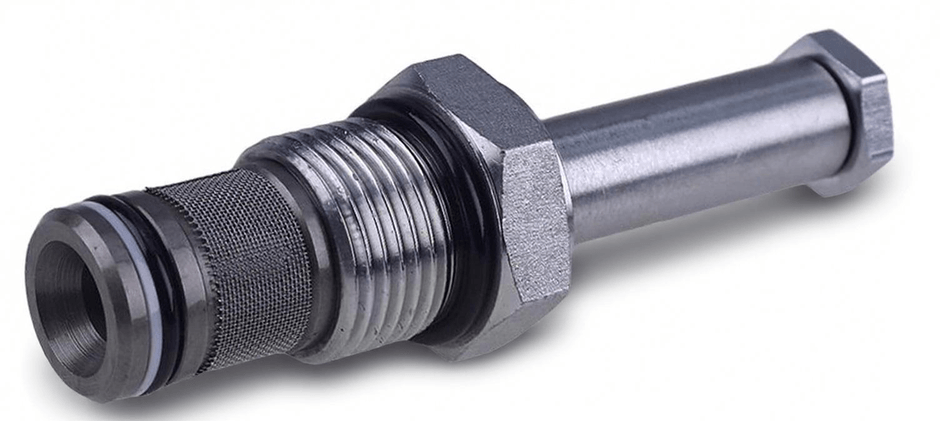

High-pressure solenoid valves handle the extreme stuff – we’re talking thousands of PSI. They use beefed-up bodies, special seals, and often pilot operation to manage forces that would destroy regular valves. Hydraulic systems and pressure washers depend on these tough customers.

Cryogenic solenoid valves work in super-cold conditions, handling liquid nitrogen, oxygen, or other cryogenic fluids. They use special materials that stay flexible at -320°F when regular seals would shatter like glass. If you’re working with anything super cold, standard valves won’t cut it.

Explosion-proof solenoid valves prevent sparks in dangerous environments. The electrical coil is sealed inside heavy-duty housings that prevent any sparks. Chemical plants, refineries, and grain elevators need these to prevent catastrophic explosions.

How to Choose the Right Solenoid Valve Material

The valve body material matters just as much as the type. Pick wrong, and your valve might corrode, crack, or contaminate your process. Here’s what you need to know:

Brass valves are the jack-of-all-trades. They handle water, air, gas, and oil beautifully. They’re affordable and resist corrosion well. Most general-purpose applications do great with brass. Just avoid them with seawater or ammonia – brass doesn’t like those.

Stainless steel valves step up when brass isn’t enough. They laugh at corrosive fluids and handle higher temperatures. Food processing, medical equipment, and marine applications typically specify stainless steel. They cost more but last forever in harsh conditions.

Plastic valves (usually PVC or polypropylene) excel with aggressive chemicals that would eat metal valves. They’re also lighter and cheaper. But they can’t handle high pressure or temperature like metal valves. Chemical dosing systems and water treatment plants use tons of plastic valves.

Quick material guide:

- Water/Air/Oil: Brass works great

- Food/Medical: Stainless steel only

- Acids/Chemicals: Plastic is your friend

- High temp (>250°F): Go stainless or special alloys

Common Solenoid Valve Problems and Solutions

Even the best solenoid valve can act up. Here are the issues we see most at FridayParts and how to fix them:

Valve won’t open: First, check if it’s getting power – use a multimeter to verify voltage at the coil. No power? Check your wiring and fuses. Power’s good? The coil might be burned out (you’ll smell it), or the valve might be stuck with debris. Try tapping it gently or cycling power rapidly.

Valve won’t close: Usually means something’s blocking the seal – a piece of debris, damaged seat, or worn seal. Sometimes the return spring breaks, leaving the valve stuck open. Pilot-operated valves might have a clogged pilot orifice preventing proper operation.

Valve leaks: Internal leaks (flow when closed) mean seal damage. External leaks around the body suggest failed gaskets or cracked housing. Both usually require valve replacement, though sometimes cleaning helps with minor internal leaks.

Buzzing or humming: AC valves can buzz if the plunger doesn’t pull in completely. This might indicate low voltage, mechanical binding, or contamination. The buzz generates heat, eventually burning out the coil. Fix it fast or buy a new valve soon.

A Note on Engine Solenoids: It’s important to distinguish the general-purpose valves discussed here from specialized solenoids found inside modern vehicle engines. If your issues are related to poor engine performance, rough idling, or a check engine light, the problem might not be with a hydraulic or pneumatic valve, but with an engine control component. For example, troubleshooting a faulty engine component requires a completely different approach. If you suspect an issue with your engine’s timing system, you’ll need a specific diagnostic guide that covers the 5 Simple Tests of Variable Valve Timing Solenoid.

Installation Tips for Long Valve Life

Want your solenoid valves to last? Installation makes all the difference. Here’s what the pros know:

Mount them right: Most solenoid valves prefer vertical installation with the coil up. This prevents debris from settling in the mechanism and helps with heat dissipation. Can’t mount vertically? At least avoid coil-down positions where moisture collects.

Use strainers: A 10-strainer upstream saves 10 strainer upstream saves 10strainerupstreamsaves100 valves. Even clean-looking fluids carry particles that jam valves. We see more valves killed by contamination than by any other cause. Protect your investment with proper filtration.

Size correctly: Oversized valves cycle more, wearing out faster. Undersized valves work too hard and fail early. Calculate your actual flow needs and size accordingly. When in doubt, ask – we help customers size valves every day at FridayParts.

Consider the environment: Hot locations cook coils. Wet areas corrode connections. Vibration loosens fittings. Plan for these challenges during installation. Heat shields, weatherproof connections, and thread locker solve many problems before they start.

FAQs

Q: What’s the difference between AC and DC solenoid valves?

AC solenoid valves run on alternating current (like your wall outlets) while DC versions use direct current (like batteries). AC valves typically pull stronger and work better for high-pressure applications. DC valves offer smoother operation, don’t buzz, and work great for proportional control or battery-powered systems. Most valves come in both versions – pick based on your available power source.

Q: Can solenoid valves work with hot water and steam?

Yes, but you need the right type! Standard solenoid valves typically handle up to 180°F. For hot water and steam, you need high-temperature valves with special seals (often PTFE or metal) and temperature-rated coils. Steam valves also need proper mounting to prevent condensate problems. Always check the temperature rating – using a standard valve on steam is asking for trouble.

Q: How long do solenoid valves typically last?

With clean fluids and proper installation, solenoid valves can last 1-3 million cycles. That’s 5-10 years in typical use. Contaminated fluids, improper sizing, or harsh environments cut life dramatically. We’ve seen valves fail in weeks with dirty fluids or last 20 years in clean systems. Maintenance matters – clean strainers and good filtration easily double valve life.

Q: Why do solenoid valves fail when brand new?

New valve failure usually means installation issues. Common culprits: debris from pipe installation jamming the valve, incorrect voltage damaging the coil, or water hammer destroying internals. Always flush lines before installing new valves, verify voltage matches the coil rating, and install water hammer arrestors in problematic systems.

Q: Can I replace just the coil on a solenoid valve?

Usually yes! Most industrial solenoid valves have replaceable coils. The coil typically costs 30-50% of a complete valve, making replacement worthwhile. Just match the voltage, wattage, and connection type. Some small or specialized valves have molded-in coils that can’t be replaced. At FridayParts, we stock replacement coils for most major valve brands.