Overview

| Operating Condition / Machine Type | Engine Air Filter Interval | Cabin Air Filter Interval |

|---|---|---|

| General Guidelines | ||

| Standard Condition | s250 – 500 hours | 500 – 1000 hours (or 1 year) |

| Severe Conditions | 50 – 200 hours | ~400 hours (or 3-6 months) |

| Extreme Conditions | 50 – 100 hours | 150 – 250 hours |

| Machine-Specific Examples | ||

| Highway Truck | 500 – 700 hours | 500 – 1000 hours (or 1 year) |

| Off-Road Truck | 150 – 250 hours | ~400 hours (3-6 months) |

| Loader / Skid Steer | 100 – 200 hours | 250 – 400 hours (3 months) |

| Excavator | 200 – 400 hours | 400 – 600 hours (6 months) |

| Bulldozer | 100 – 150 hours2 | 50 – 400 hours (3 months) |

The air filter can mainly be divided into two types: engine air filter and cabin air filter. The former helps your machinery run clean while the latter offers you a comfortable operating environment. For more details, you can read: the engine & cabin air filter difference. But how often should you change your air filter, and what’s the sign to change it? Many people are confused about this. So this guide will help you figure out the recommended schedule both for standard conditions and specific machine types. Read now to learn the maintenance tips and find a quality air filter for your machinery!

Standard Conditions Replacement Schedule

Engine Air Filter

The engine air filter stops abrasive dust, dirt, and debris from entering the engine, where they can cause catastrophic damage to pistons, cylinders, and other internal components.

Standard Disposable Pleated Filters: They should typically be replaced every 250-500 operating hours. When their working condition are severe, it should be shortened to every 50-200 operating hours.

Cabin Air Filter

While the engine filter protects the machine, the cabin air filter protects the operator. It filters the air entering the operator’s cab, removing dust, pollen, and soot. And it is usually the standard & carbon-activated filters.

Standard & Carbon-Activated Filters: They should typically be replaced every 500-1000 operating hours or annually. When their working conditions are contaminated, this period can be shortened to every 3-6 months.

Machine-Specific Replacement Schedules

While general guidelines are a good start, your machine’s specific job dictates the true replacement frequency. The following recommendations integrate the likely operating conditions for each machine type.

- Trucks: For on-highway use (Standard Conditions), replace engine air filters every 500-700 hours. In dusty off-road use (Severe Conditions), shorten this to every 150-250 hours. For on-highway use, cabin air filters can be changed according to the standard schedule of 500-1000 hours or annually. In dusty off-road use, this should be shortened to approximately 400 hours or every 3-6 months, whichever comes first.

- Wheel Loaders & Skid Steers: These machines typically operate in persistently dusty environments (Severe to Extreme Conditions). Replace engine air filters every 100-200 hours. Cabin air filters need frequent changes, typically every 250-400 hours or 3 months, whichever comes first.

- Excavators: Due to higher air intake volumes, replace engine filters every 200-400 hours under normal digging conditions. For demolition or quarry jobs (Extreme Conditions), this interval should be shortened to align with the Extreme Conditions guideline of 50-100 hours. Cabin filters should be replaced every 400-600 hours or approximately 6 months, whichever comes first.

- Bulldozers: In typically dusty earth-moving conditions (Severe to Extreme Conditions), change engine filters every 100-150 hours. To maintain safe air quality, cabin filters require replacement every 250-400 hours or 3 months, whichever comes first.

Signs to Replace Your Air Filter

While following a service schedule is a great practice, the real-world conditions of your job site are the ultimate test. Your machine will give you clear signals when a filter is clogged and needs immediate attention. Ignoring these signs can lead to reduced performance and costly damage.

Here are the key indicators for both your engine and cabin air filters.

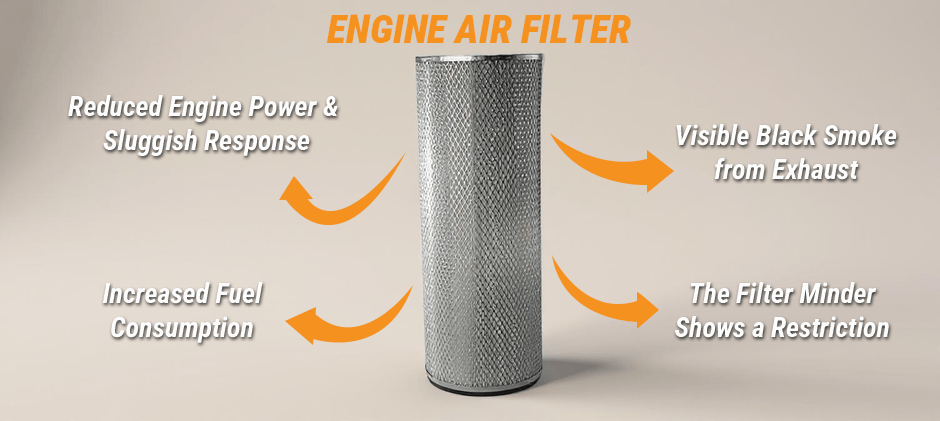

4 Signs Your Engine Air Filter Needs Replacing

A clogged engine filter starves your powertrain of the air it needs to perform. Look out for these critical symptoms:

- Reduced Engine Power & Sluggish Response: This is often the first sign. If your machine feels weak, struggles to lift a load, or is slow to respond, a blocked air filter is the most likely culprit.

- Increased Fuel Consumption: An engine working harder to pull in air burns more fuel to do the same amount of work. If you notice you’re refueling more often, check the filter immediately.

- Visible Black Smoke from Exhaust: Black smoke indicates an improper air-to-fuel ratio (too much fuel, not enough air), and a clogged filter is a primary cause of this incomplete combustion.

- The Filter Minder Shows a Restriction: This is your machine’s built-in diagnostic tool. If the filter minder is in the red or shows a “restricted” status, trust it. Replace the filter, even if it’s ahead of schedule.

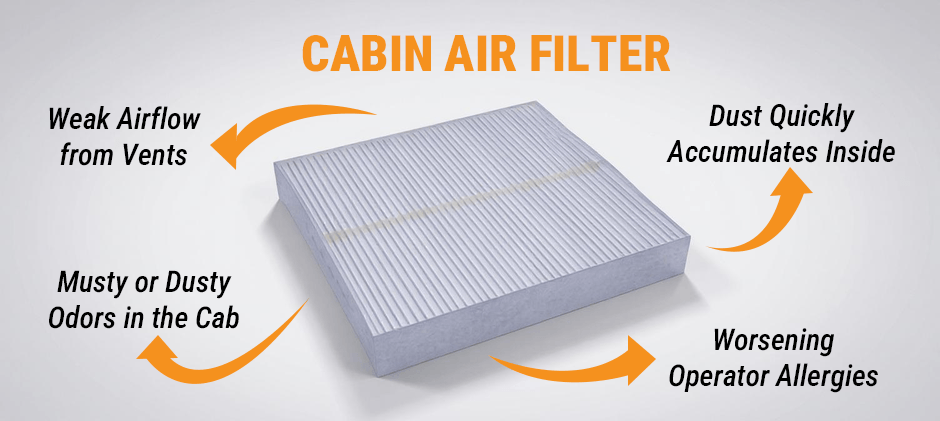

4 Signs Your Cabin Air Filter Needs Replacing

A dirty cabin filter directly impacts the operator’s health, comfort, and ability to work effectively.

- Weak Airflow from Vents: If you have the fan cranked up but only a weak stream of air is coming out, the filter is almost certainly clogged with dust and debris.

- Musty or Dusty Odors in the Cab: A foul, musty smell is a classic sign that mold and bacteria are growing on a damp, dirty filter. This directly affects the air you breathe.

- Dust Quickly Accumulates Inside: If you find a constant layer of dust settling on the dashboard and controls, it means the filter is no longer trapping particles and is instead letting them blow right into the cab.

- Worsening Operator Allergies: For operators with allergies, a sudden increase in symptoms while working is a strong indicator that the filter is failing to capture airborne dust, pollen, and soot.

4 Factors Influencing How Often You Should Replace Air Filters

A manufacturer’s service schedule offers a helpful baseline, but it is not a strict rule. The actual lifespan of your air filters depends on the specific demands of your work environment.

Several important factors can significantly reduce the replacement interval, requiring more frequent inspections to safeguard both your engine and your operator.

1. Operating Environment & Material Type

This is the most critical factor. A machine working in a rock quarry, a demolition site, or a dry agricultural field will ingest far more contaminants than one used in a grassy park. Fine, abrasive particles are especially harmful and need more frequent changes.

2. Machine Use and Workload

How a machine is operated directly affects filter load. A wheel loader constantly moving fine sand faces more stress than one handling larger rocks. Similarly, a machine running 12 hours daily in dusty conditions will need more frequent service than one used only occasionally on the same site.

3. Weather and Seasonal Conditions

The season and local weather are key factors. Dry, windy days can turn a typical job site into a harsh environment with a lot of dust. Although wet conditions reduce airborne dust, splashed mud can still clog intake pre-cleaners.

4. Operator Health & Cabin Condition

For the cabin air filter, the operator’s health is the main concern. If the operator has allergies or works with irritants like silica, changing the filter more often is necessary. A clean filter is also vital for maintaining the cab’s positive air pressure, which helps prevent dust from entering.

Why Is Regularly Replacing the Air Filter Important?

Failing to replace your air filters on schedule is not a shortcut to saving money—it’s a direct path to higher costs, increased downtime, and serious safety risks. Both the engine and cabin air filters perform critical functions, and neglecting them has significant consequences for your equipment and your operator.

For Your Engine: Protecting Your Investment

The engine air filter is the first line of defense for your machine’s most valuable component. When it becomes clogged, the entire powertrain suffers.

- Prevents Catastrophic Engine Damage: A dirty filter allows fine dust and abrasive particles to enter the engine, causing accelerated wear on pistons, rings, and cylinder walls. This strain can lead to a complete system breakdown, resulting in extremely costly repairs and extended downtime.

- Maintains Fuel Efficiency: When a filter is clogged, the engine must work much harder to draw in air. This continuous struggle means it consumes significantly more fuel to produce the same amount of power, directly increasing your daily operating costs.

- Ensures Full Performance: A clean air filter is essential for optimal combustion. A restricted airflow starves the engine, leading to sluggish performance, reduced power, and black smoke from the exhaust—all of which hinder productivity on the job site.

For Operator: Ensuring Health and Safety

The cabin air filter plays a major role in ensuring the operator’s comfort, health, and focus throughout the workday.

- Improves Air Quality and Operator Health: The filter is the only barrier protecting the operator from the outside air, which is often filled with harmful contaminants like silica dust, pollen, mold spores, and exhaust fumes. So regularly replacing it is crucial for preventing respiratory irritation and long-term health issues.

- Optimizes the Climate Control System: Just like in an engine, a clogged cabin filter forces the HVAC system to work harder to push air into the cab. And this strain can damage the fan motor and other components, leading to costly repairs and an uncomfortable work environment for the operator.

- Increases Comfort and Reduces Fatigue: A clean filter ensures strong, consistent airflow, allowing the heating and air conditioning to work effectively. And a comfortable operator is a more alert and productive operator, making a clean cabin filter a key component of job site safety.

Air Filter Maintenance Tips

While adhering to a replacement schedule is essential, proactive maintenance habits can help you get the most out of every filter, improve overall machine performance, and prevent unnecessary downtime. Integrating these simple checks into your daily routine can make a significant difference.

1. Perform Daily Visual Inspections

Before starting your shift, make it a habit to check the engine’s air filter minder or restriction indicator. This gauge gives you a real-time status of airflow. Additionally, a quick visual check of the filter itself can tell you if it has problems due to the unexpected conditions, regardless of its service hours.

2. Regularly Service the Pre-Cleaner

Most heavy equipment is fitted with a pre-cleaner designed to eject heavy dust, dirt, and debris before it ever reaches the primary filter. Check the dust ejector valve or collection bowl daily and empty it as needed. A functional pre-cleaner can extend the life of your main filter by up to 10 times, making this one of the most effective maintenance actions you can take.

3. Clean the Filter Housing, Not the Filter

When it’s time to replace a filter, always wipe out the inside of the filter housing with a clean, damp cloth before installing the new one. This removes any settled dust that could be instantly sucked into the engine on startup. Never use compressed air to clean a primary filter. While it may look cleaner, high-pressure air creates microscopic tears in the filter media, allowing fine, engine-destroying particles to pass directly into your engine.

4. Keep the Operator’s Cab Clean

Just as vacuuming a home reduces the load on an HVAC filter, keeping the cabin interior clean helps the cabin air filter last longer. Regularly wiping down surfaces and cleaning the floor mats prevents dust, dirt, and debris from being constantly recirculated and pulled into the ventilation system, ensuring cleaner air for the operator.

5. Always Keep Spares on Hand

Downtime on a job site is expensive. An unexpectedly clogged filter due to severe conditions can bring a critical machine to a halt. Keeping a spare set of engine and cabin air filters for each machine is a low-cost insurance policy that ensures you can get back to work in minutes, not hours or days.

Find the Right Air Filter to Extend Your Equipment’s Lifespan!

Learning this, you must have a good command of the air filter maintenance schedule & signs & tips. Now, follow this guide and select a quality air filter to perform it yourself! If you don’t know where to find a reliable part, FridayParts is a good choice. You can directly visit FridayParts to find the compatible and qualified air filter right now. Our products have OEM quality without OEM price tag. For specific replacement costs, you can read: How Much Does Air Filter Replacement Cost in 2025? Order today to restore your equipment and extend its lifespan!