Tail lights on heavy equipment are primarily designed to enhance safety on the job. They don’t directly serve you, but rather act as a warning signal to others approaching you. The tail lights allow those behind to clearly see the location, direction and driving status of the device. If the tail lights break, it’s best to fix them as soon as possible to avoid danger. How much does it cost to fix a tail light? As for the cost of repair, the difference is quite big. It depends on what kind of equipment it is, what went wrong, and whether you change the light bulb yourself or ask someone to help repair it.

Broken Tail Lights Increase The Risk of Accidents

On a construction site, in an environment like a farm, visibility is safety. Unlike a car that follows a route on a highway, people often move around off-road equipment, and various devices may move in different directions. At this time, the tail lights become a key signal for others to judge where you are, whether you are moving or stopping.

If the tail light breaks down, someone else won’t be able to see your device from behind. A loader, truck, or other operator may not be able to spot you slowing down or stopping in time, and the risk of a crash is high. Such an accident will not only damage equipment and delay work, but may also hurt people. On the worksite, the tail lights are a lifeline. If it doesn’t light up, then a machine weighing several tons is like a moving blind spot, especially when there is dust or light, which is more dangerous.

Why Do Tail Lights Fail?

The tail lights of equipment such as tractors, loaders, and excavators are actually quite durable and last longer than those of ordinary cars. If something goes wrong with them, it’s usually because the harsh working environment has damaged them — constant vibration, dust, muddy water, flying stones, or water getting into the wiring — rather than because the bulb has simply reached the end of its life.

Burnt-Out Bulb

Traditional halogen bulbs emit light by heating and have a thin filament inside. Heavy equipment vibrates particularly hard when working, and this filament is easily broken. Although halogen bulbs are cheap, they tend to break easily after a short time in this environment, and they are replaced frequently. If you still don’t know how to change the tail light bulb, you can actually learn it.

Physical Damage

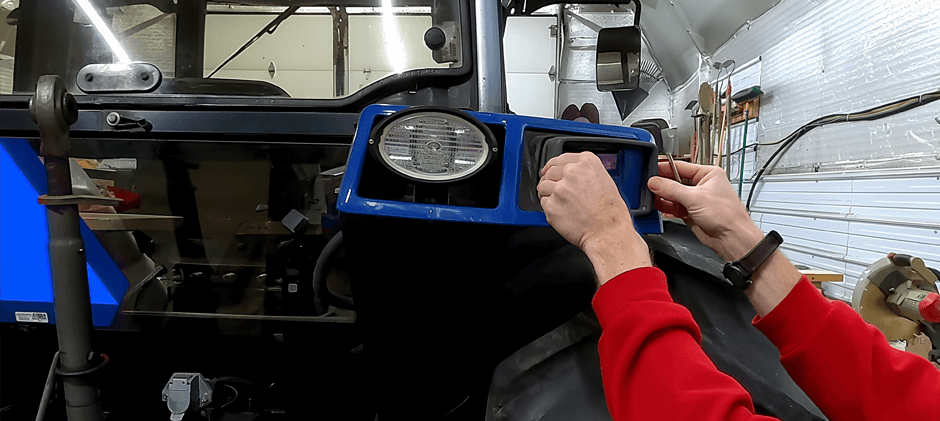

The tail light lenses or the whole casing of the tail lights are quite easy to break. When a flying stone hits it, when you back into something, or when you accidentally scrape it while moving around the site, it can crack or even break. Once the shell breaks, water and dust easily get inside and damage the circuitry and the bulb.

Wiring and Connection Issues

This is a very common problem with off-road equipment.

- Vibration: Vibration is a big problem. The machine is always shaking. Over time, the electric plug behind the tail light may become loose, or the wires may be shaken and rub against the frame, and finally short-circuit due grinding of the insulation layer.

- Corrosion: Machinery is often flushed by water cannons, or works in rain or mud, and water vapor can easily get into plugs and light bulb holders, causing rust and poor contact after a long time. Once the socket is rusty, even if you replace it with a new light bulb, it may not light up.

Blown Fuse

The fuse is a protective device. It sometimes breaks due to aging, but more often, the line is short-circuited. If you put on a new fuse and it burns up again, it means there’s still something wrong with the line.

Faulty Light Switch

Light switches can also be problematic after being used for a long time. It’s just not as common as light bulbs or lines.

Before buying a part, simply check it yourself. First, check whether the light bulb is broken, and then look for any obvious damage, rust, or loose wires. Many times, you just need to clean a dirty connector or replace a burned-out bulb instead of spending money on an entire new assembly.

How Much Does It Cost to Fix a Tail Light?

How much does it cost to fix a tail light? The answer depends on three main factors: the type of failure, the specific part needed for your machine’s make and model, and whether you do the work yourself or hire a professional.

DIY Bulb Replacement

If the only problem is with the bulb, this is your most affordable fix.

- Halogen Bulb: A standard halogen bulb for heavy equipment costs between $5 and $15.

- LED Bulb (Upgrade): A direct replacement LED bulb can cost between $15 and $40, but it offers far greater resistance to vibration and a much longer lifespan.

Full Assembly Replacement (DIY)

Often, the entire tail light housing is damaged or corroded, making it impossible to repair simply. In this case, replacing the entire unit is the best solution. At this point, after-sales accessories can be of great value. For a fraction of the dealer’s price, you can get a high-quality replacement that meets or exceeds the original factory specifications.

| Equipment Brand | Aftermarket Price Range |

|---|---|

| Bobcat | $50 – $110 |

| New Holland | Around $90 |

| John Deere | Around $90 |

| Caterpillar (CAT) | Around $60 |

| Volvo | Around $160 |

| Ford, Dodge, Chevy | $140 – $700+ |

| Can-Am, Polaris, Yamaha | $23 – $90 |

| Shorelander | Around $110 |

Based on our inventory for popular off-road machinery, here is what you can expect to pay for aftermarket assemblies: As you can see, replacing the entire LED tail light assembly of a regular skid steer loader only costs $50 to $100. For a critical security component, the money was well spent. While replacing the tail lights, you should also evaluate the overall visibility of the machine and consider adding a powerful LED work light to improve the front lighting.

Professional Repair

If you’re not very familiar with the wiring or don’t have time to do it yourself, you can get a mechanic who repairs heavy equipment to help.

- Labor Costs: Generally speaking, their labor costs are somewhere between $75 and $150 an hour.

- Simple Replacement: If you just change the tail lights, the work is quite simple. Usually it can be done in less than an hour, which is only 70 to 80 to more than 100 yuan, including labor, plus the price of the lights.

- Complex Diagnosis: But if it’s a short circuit or electrical issue, it gets tricky. You may need two or three hours to check it, and the labor could cost around $150 to $450.

What to Consider When Shopping for Tail Lights?

Lots of tail lights on the market. To help you narrow down your options, here are a few things to consider when purchasing a tail light:

Compatibility

Heavy equipment models have very specific mounting points and electrical connectors. Always double-check that the part number is compatible with the specific year, brand, and model of your machine.

Bulb Type: Halogen vs. LED:

- Halogen: Lower upfront costs. However, they are more susceptible to vibration, have a shorter lifespan, consume more power, and require replacement more frequently.

- LED: Although LED lights are more expensive at first, they are definitely worth using in off-road equipment. It is a solid-state structure, which is particularly resistant to earthquakes and impacts, can last up to tens of thousands of hours in life, is brighter, and saves more power. In environments like construction sites and farms, LEDs are basically the most reliable choice.

Source: OEM vs. Aftermarket:

- OEM parts sourced directly from the machine’s manufacturer (e.g., Caterpillar, Bobcat). They are a guaranteed fit but come with a very high price tag.

- Aftermarket tail lights perform just as well as factory ones. They’re also more affordable because third-party manufacturers make them, making them a good option if you’re shopping on a budget.

Get a Replacement Tail Light

Damaged tail lights on off-road equipment are a safety hazard that cannot be ignored. Repairing it is often easy and affordable. How much does it cost to fix a tail light? A simple light bulb costs less than $20, while a complete set of high-quality skid steer loader aftermarket LED components costs around $50 to $100. As mentioned earlier, one of the things that should be considered when looking for new stop lamps is compatibility. This can also be said to be the most critical part, because if you order an incorrect lamp, you will be wasting your time and money. Fortunately, FridayParts makes it easier to find the right one. Directly enter your brand and model in the search bar to show the lights that match the equipment. Our catalog has accurate and detailed information about parts. If you have any questions, please do not hesitate to contact us.