As temperatures rise, it’s a smart move to upgrade the radiator in your equipment’s cooling system. But once you start searching online, the choices—and opinions—can get overwhelming fast. Which radiator core is right for my machine? Should you go with a 2-core or 3-core radiator? Which materials offer the best durability?

Don’t worry—this article covers. Whether you’re a machine owner, maintenance tech, or parts buyer, this guide breaks down everything you need to know in plain, practical terms. By the way, we share the latest trends in cooling system components to watch for in 2025.

What Is a Radiator Core?

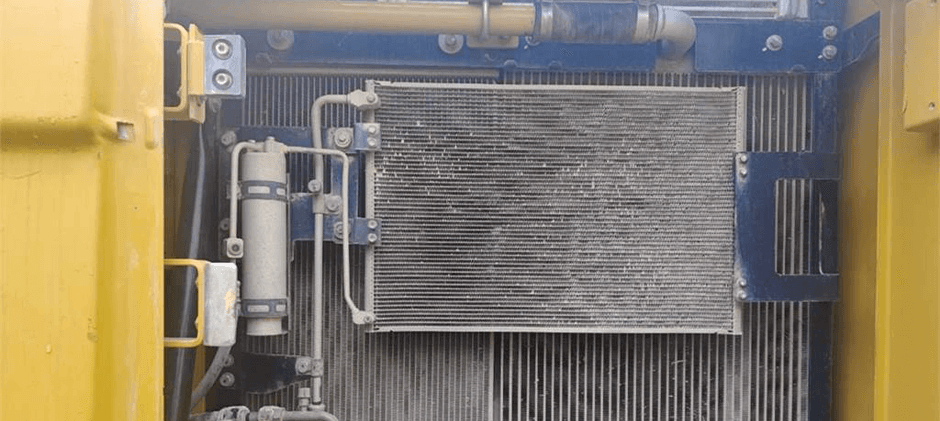

Let’s begin with the basics. The radiator core is the central working part of the radiator—it’s where the heat is released from the engine. You can think of it as the heart of the entire cooling system. It typically consists of three main parts

- Tubes: These are the small channels that carry the hot engine coolant from one side of the radiator to the other.

- Fins: These are the thin, wavy sheets of metal attached to the tubes. Their job is to pull heat away from the coolant and transfer it to the air that blows through the radiator.

- Headers: These are the plates at the top and bottom (or on the sides) of the core.

The design, size, and material of these three parts determine whether the radiator core can effectively keep the engine cool. Knowing these will greatly help you choose the radiator core, such as how many row cores to choose.

How to Choose the Correct Radiator Core?

The right radiator core for your equipment can ensure proper engine cooling, prevent overheating, and avoid unnecessary repair costs. When considering upgrading your heavy machinery engine, there are 4 key things to get the right one:

1. Match the Radiator Core to the Equipment Size

A radiator core for a compact tractor won’t work for a large bulldozer. Smaller engines create less heat and need a lighter radiator core with fewer fins. In contrast, bigger equipment with high-horsepower engines generates more heat and requires a larger, more robust radiator core with additional fins and rows for efficient cooling.

2. Consider Engine Power

Your engine’s horsepower directly affects how much heat it produces. The higher the horsepower, the more demanding the cooling system. Choose a radiator core with enough surface area and coolant capacity to handle the engine’s heat output. This helps avoid overheating and keeps the engine running smoothly, even under tough conditions.

3. Factor in Workload and Environment

Think about how your equipment is used. A loader or excavator used for heavy-duty tasks generates more heat over time and needs a radiator core that can keep up. Also, consider the working climate. Machines operating in hot regions—like Texas in summer—require more efficient cooling solutions than those in milder climates. A well-matched radiator core ensures your machine performs reliably in any environment.

4. Check Fitment and Dimensions

Always compare the dimensions of your original radiator core with the one you plan to purchase. Engine bays can be tight, and installing a core that’s too big or too small can lead to fitting issues or reduced cooling efficiency. Stick to the correct length, width, and thickness for proper installation and performance.

Cooling system technology is evolving fast, and 2025 is shaping up to bring some important upgrades. New aluminum alloys and protective coatings are making radiator cores tougher and more corrosion-resistant—perfect for off-road equipment. Updated designs, such as louvered fins and dimpled tubes, are increasing heat transfer without needing larger cores. And when it comes to buying parts, the gap between aftermarket and OEM is closing. Today’s high-quality aftermarket cores can deliver outstanding performance at a lower cost. It’s smart to compare specs and choose suppliers with strong customer reviews before making a purchase.

How Many Core Rows Should You Choose?

One of the most common ways to describe a radiator core is by its number of rows. A “row” is simply a line of tubes running from the inlet to the outlet. The number of rows is a key factor in cooling performance.

1-2 Row Cores: These have one or two rows of tubes. They are thinner, which allows air to pass through them more easily. This is a big advantage in dusty or muddy off-road conditions because they are less likely to get clogged with debris. They are great for standard-duty machines or smaller engines.

3-4 Row Cores (or more): These thicker cores have three, four, or even more rows of tubes. This design gives them a much larger coolant capacity and more surface area for heat transfer. They are the best choice for high-horsepower engines, heavy-duty applications, and hot climates. They are more suitable for high-power or off-road use.

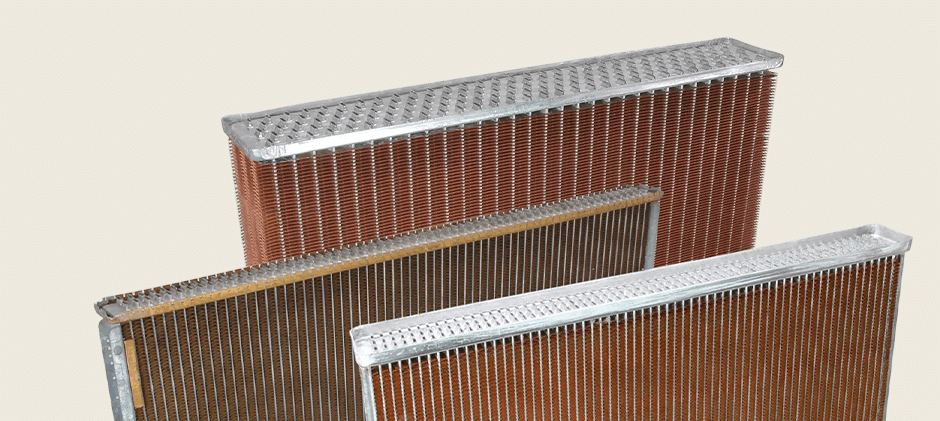

In addition to paying attention to the number of core rows above, you can also pay attention to the material of the radiator core, which has a greater impact on its performance and durability. The most common materials are copper-brass and aluminum. Copper-brass cores are the traditional choice—great for heat transfer and easy to repair, but heavier. Aluminum cores, now the industry standard, are lighter and efficient but a little harder to fix if they leak. Based on the above tips, you can focus on the points you care about when choosing a heat sink core.

Common Mistakes to Avoid

Choosing the wrong radiator core can be costly. Here are some common mistakes we’ve seen customers make over the years.

- Ignoring the Dimensions: This seems basic, but it happens. Someone orders a core based on the machine model alone, without checking the exact dimensions. They end up with a core that’s too thick or has the wrong mounting points, leading to a frustrating installation or a return.

- Underestimating Cooling Needs: This is a classic mistake. To save a little money, someone might choose a 2-row core for a machine that really needs a 3-row. The machine then constantly runs hot under load, leading to reduced performance, accelerated engine wear, and potential downtime.

- Ignoring Material and Build Quality: Not all cores are created equal. A cheap, low-quality core might use thinner metal for the fins and tubes or have weak welds. These will not stand up to the vibration and pressure of a heavy-duty work environment and are prone to premature failure.

Don’t cut corners when it comes to your cooling system. Some buyers go for the cheapest radiator cores to save a few bucks, only to end up with cracked seams and costly engine damage just months later. Years of experience have taught us that quality is critical when it comes to cooling systems. Choosing high-quality cooling components can save you more time and energy.

Conclusion

Choosing the right radiator core is key to keeping your heavy equipment running safely and efficiently. It’s not just about cost—you also need to consider engine size, workload, and the environment. By focusing on quality, material, and the right core size, you can avoid overheating and costly repairs.

When it’s time to replace your radiator core, trust a reliable supplier. At FridayParts, we offer a wide selection of durable, high-quality cooling parts at fair prices. Visit our website to find the right fit for your machine and keep your equipment cool and working strong.