You fix misfires faster when you know what each part does. Spark plugs make the spark, and ignition coils supply the high voltage that powers that spark. This guide shows off-road machinery owners how to spot Ignition Coils vs Spark Plugs problems, how to test safely, and how to choose replacements that last in dust, water, and vibration.

Ignition Coils vs Spark Plugs: What’s the Difference?

Spark plugs ignite the air‑fuel mix inside the cylinder. A spark plug is a wear item, so it slowly erodes and gets harder to fire over time.

Ignition coils create the high voltage that the plug needs. A coil is more like an electrical transformer, and it usually fails from heat, vibration, moisture, or internal insulation breakdown.

This guide is for gasoline engines. Diesel engines usually do not use ignition coils or spark plugs (they use compression ignition, and may use glow plugs instead).

“A weak plug can look like a bad coil, and a weak coil can look like a bad plug—so test before you buy.”

When Should You Suspect the Spark Plug?

Suspect the spark plug when the problem is gradual, and maintenance is overdue. Plugs often fail slowly, especially if hours are high or fuel quality is poor.

6 Symptoms of Bad Spark Plugs

Bad plugs usually show up as weak starting and rough running. Common signs include:

- Hard starts, especially cold starts

- Rough idle that improves at higher RPM

- Lower power under load (climbing, pushing, towing)

- Worse fuel economy than normal

- Engine “hunts” or surges at steady throttle

- Visible plug wear, heavy deposits, or damaged porcelain

A single fouled plug can cause a big miss. Off-road machines idle a lot, and idling can carbon-foul plugs.

3 Quick Checks for Spark Plugs

You can learn a lot from one plug inspection.

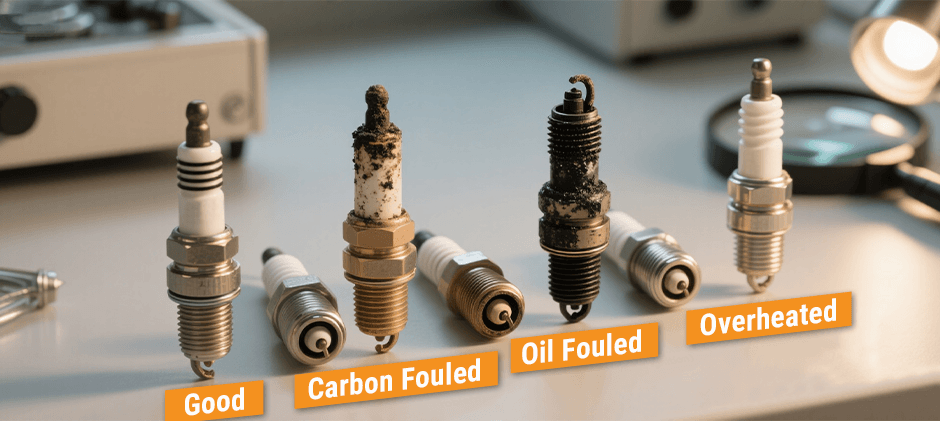

- Remove and read the plug: look for heavy carbon, oil, a cracked insulator, or a rounded electrode.

- Check the gap: an over-wide gap makes the coil work harder and increases misfire risk.

- Swap test (if easy): move the plug to another cylinder and see if the misfire follows.

“If the plug gap grows, the coil must push higher voltage to jump the gap.”

When Should You Suspect the Ignition Coil?

Suspect the ignition coil when the misfire is sudden or gets worse when hot or wet. Coils can fail in a way that seems random: fine at idle, bad under load.

6 Symptoms of a Bad Ignition Coil

Bad coils often fail under load because voltage demand rises. Common signs include:

- Sudden misfire that appeared “out of nowhere.”

- Misfire under acceleration, climbing, or deep snow/mud load

- Engine runs worse after warming up (heat soak)

- Misfire in rain, after washing, or in high humidity

- Intermittent stalling and restarting. (Problems with a related part, the ignition control module, can also cause similar issues.

- Smell of hot plastic, melted boot, or visible arcing marks

Moisture tracking is a big clue. If the coil boot or plug well is wet/dirty, a spark can leak to ground instead of firing the plug.

4 Quick Checks for Ignition Coils

Simple checks can confirm a coil problem without guesswork.

- Visual check: cracks, burn marks, melted boot, loose connector, corrosion.

- Swap test (coil-on-plug engines): swap coils between cylinders and see if the misfire follows.

- Spark test with the right tool: use an adjustable spark tester, not “hold it near metal.”

- Scan for misfire codes (if equipped): note which cylinder is counting misfires. A specific coil code like P0356 can confirm the diagnosis.

“Test, don’t guess—swap tests are the fastest way to separate coil faults from plug faults.”

Why Do Off-Road Machines Kill Coils and Plugs Faster?

Off-road use adds heat, dirt, water, and vibration. Those four things shorten ignition life even if the engine is not “old.”

5 Reasons Off-Road Ignition Parts Fail Early

These are the common killers on UTVs, ATVs, and work trucks.

- Dust and mud contamination around boots and plug wells

- Water intrusion from washing or deep crossings

- Long idling and short trips that foul plugs

- High under-hood heat and poor airflow at low speed

- Vibration that loosens connectors and stresses coil windings

Small problems stack up. A slightly wide plug gap plus a little moisture can push a marginal coil over the edge.

How do you diagnose coil vs plug step by step?

Follow a simple order so you don’t replace good parts. Start with the easiest checks and move toward testing.

7 Steps to Diagnose Safely

This process works for most gasoline off-road machines.

- Confirm basics: fresh fuel, clean air filter, tight battery terminals.

- Check for obvious damage: broken wires, loose coil connectors, water in plug wells.

- Read codes and freeze-frame data (if available).

- Inspect the spark plug: gap, deposits, cracks, electrode wear.

- Swap test: swap the plug or coil to another cylinder and re-check the symptom.

- Use a spark tester: look for a strong, consistent spark under cranking.

- Fix the root cause: seal boots, clean moisture, repair wiring, and correct plug gap.

High voltage is a real danger. Work with the engine off when disconnecting ignition parts, and keep sparks away from fuel vapors.

“A clean diagnosis beats a pile of new parts.”

How to Prevent Repeat Failures?

Replace parts in a way that reduces stress on the whole ignition system. A new coil can still misfire if the plug is wrong or the gap is too large.

5 Tips for Long-Lasting Repairs

These habits prevent comebacks.

- Replace worn plugs on schedule, not only after a misfire.

- Set the correct plug gap (and avoid bending fine-wire tips).

- Replace damaged boots and seals to keep water out.

- Use dielectric grease only where the manual recommends (usually inside the boot).

- Fix oil leaks that soak plugs and boots.

One weak part can damage the other. A worn plug forces higher coil voltage, and a weak coil can foul a plug.

How to Choose the Right Parts for Your Machine?

Match parts to your exact engine and ignition style. “Looks the same” is not the same as “fits and works.”

These details prevent misfires and early failure.

- Engine model and year (and VIN/serial when possible)

- Spark plug type and heat range recommended by the maker

- Plug reach and seat style (gasket vs taper)

- Coil connector type and mounting style

- Coil type (coil-on-plug vs coil pack vs distributor system)

Correct parts save time. The wrong heat range or wrong reach can cause poor running or even engine damage.

When to Replace Ignition Coils vs Spark Plugs?

Replace both when you want the fastest, most reliable fix in harsh use. This is common if hours are high or you see heat and moisture damage.

Replace both if:

- The plug is clearly worn/fouled, and the coil boot is cracked or carbon-tracked

- Misfire follows the cylinder even after cleaning and resealing

- You had repeated misfires under load, and the machine works in wet mud/snow

“If you don’t remove the cause, the new part becomes the next failure.”

Summary

Spark plugs wear out slowly, and ignition coils often fail from heat, moisture, and stress under load. Use plug inspection, swap tests, and a proper spark tester to pinpoint the real problem before buying parts. When you’re ready to replace, choosing the correct fit for your exact engine saves the most downtime—check FridayParts for a matching spark plug and ignition coil so you can get back to work with a clean, strong spark.