A Diesel Particulate Filter is a highly efficient soot catcher — essential for meeting modern emission rules like EPA Tier 4 Final or EU Stage V. A well‑maintained DPF keeps your machine running clean and legal. But if neglected, it can cause power loss, downtime, and costly repairs.

This guide explains how it works, what can go wrong, and how to keep it healthy.

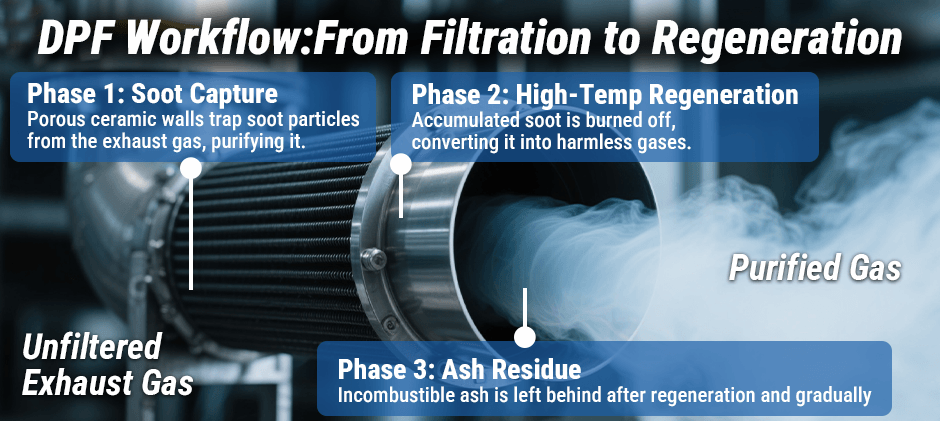

How Does the DPF Regeneration Cycle Work

It can’t hold soot forever. It periodically cleans itself through a process called regeneration, which burns off trapped soot at high temperature, leaving behind a small amount of ash.

There are three types of regeneration:

1. Passive Regeneration

- Happens automatically when the machine works under heavy load.

- Exhaust temperature naturally exceeds 300 °C (575 °F) and burns soot continuously.

- No operator action needed — this is the most efficient mode.

2. Active Regeneration

- Occurs when the exhaust isn’t hot enough (light duty or long idling).

- The ECU injects a bit of diesel into the exhaust system, raising the DPF temperature to 600 °C (1100 °F) or more.

- You may notice higher idle RPM or a change in engine tone during this process.

3. Manual (Forced) Regeneration

- Needed when active regen is interrupted or incomplete.

- A DPF warning light will appear — park in a safe area and press the manual regen button.

- Takes about 20–40 minutes.

Safety Tip: Exhaust gets extremely hot during regeneration. Never perform the process near flammable materials such as dry grass, fuel, or hydraulic oil.

6 Warning Signs When Your DPF Needs Attention

Ignoring DPF alerts can cause engine derate or shutdown.

Here’s how to interpret common signals:

- Flashing DPF Light → It is nearing full; operate under heavier load or perform a manual regen soon.

- Solid DPF Light → Immediate manual regeneration required.

- DPF + Check Engine Light → Filter is critically clogged. The engine may derate; dealer service needed.

- Reduced Power (Derate) → ECU limits power output to prevent damage.

- Higher Fuel Use → Engine works harder to push exhaust through a clogged filter.

- Visible Smoke or Odor → DPF malfunction. A healthy one = no visible exhaust smoke.

Common Causes of DPF Problems

Its failures are rarely random — they result from operating habits or incorrect maintenance.

The biggest culprits in off‑road machinery are:

1. Excessive Idling or Light Loads

- Not enough heat for passive regeneration.

- Causes frequent forced regenerations and quicker clogging.

2. Wrong Engine Oil

- Always use low‑ash oil (API CJ‑4 / CK‑4 / ACEA E6 or E9).

- Regular oil forms unburnable ash that permanently clogs the filter.

3. Ignoring Warnings

- Operating after the DPF light appears can change a quick fix into a major repair.

4. Sensor Failures

- Faulty temperature or pressure sensors can mislead the ECU, preventing proper regeneration.

How to Prevent DPF Failures and Downtime

Keeping your DPF healthy saves money and uptime. Follow these practical tips:

1. Work, Don’t Idle

- Avoid long idling.

- Let the machine operate under moderate load to maintain exhaust heat.

2. Respond Quickly to Warnings

- Treat DPF lights like a fuel light — act immediately.

- Perform manual regeneration when prompted, and don’t interrupt it.

3. Use Correct Fluids

- Engine Oil: Always use manufacturer‑approved low‑ash types.

- Diesel Fuel: Only use Ultra‑Low Sulfur Diesel (ULSD) to protect the system.

4. Service on Schedule

- Most manufacturers recommend professional DPF cleaning every 3,000–5,000 hours.

- The filter is removed and cleaned (“baked and blown”) to restore performance.

Final Takeaway

It isn’t optional — it’s essential for emissions compliance and engine performance. Tampering with or deleting it is illegal in most regions and can cause severe ECU errors.

By understanding how regeneration works and keeping to proper maintenance and fluids with FridayParts, you’ll ensure your DPF stays reliable, your machine stays productive, and your investment stays protected.