Does your tractor or excavator’s AC only work when you are driving? This is common on off-road machines. The cause is often easy to find if you check things in the right order.

This guide explains why it happens and gives a simple step-by-step plan to help you fix it so the cabin stays cool even at idle.

Why Does This AC Problem Happen?

When your machine is idling, the engine is turning slowly, and the machine is not moving. When you start driving or working, two helpful things happen:

- The engine RPM usually goes up.

- More air moves through the front of the machine.

If the A/C only works while moving, it usually means the system is barely working. It can handle “easy mode” only when RPM or airflow increases.

The #1 Reason: Poor Condenser Airflow

Most of the time, the problem is not enough airflow through the condenser. On farms and job sites, the condenser can get packed with dust, grass, and dirt.

If you only check one thing first, check this.

What Is the AC Condenser and Why Is Airflow Critical?

The condenser is like a small radiator for your A/C. It is usually at the front of the machine, often in front of the engine radiator.

Its job is to dump heat from the refrigerant to the outside air.

Clear Statement: “If heat cannot escape the condenser, the A/C pressures go too high, and the system may shut the compressor off to protect itself.” You can learn to spot the 7 key signs of a faulty A/C condenser to diagnose this issue early.

At idle, there is very little natural airflow. Therefore, the A/C relies heavily on the cooling fan to draw air through the condenser. When you drive, “ram air” (air pushed in by forward motion) helps a lot.

2 Symptoms of Poor Airflow

- Cold then warm at idle: It may blow cool for a short time, then turn warm or humid as pressure rises, and the compressor shuts off.

- Cold when moving or at higher RPM: When you rev the engine or drive, airflow increases, pressure drops, and cold air comes back.

How to Fix Poor Airflow Issues

Do these checks with the engine off and cool. The front of a machine can be hot and sharp.

Step 1: Thoroughly Clean the Condenser

This is the most important step. The gap between the condenser and radiator often traps debris. For a detailed guide on this process, see our article on how to clean a radiator for off-road machinery.

- Get a good look. Use a flashlight. Check the condenser fins and the space behind it.

- Use compressed air (best method). Blow from the engine side outward so you push debris back out the way it came in.

- Use a pressure washer carefully. Use low pressure. High pressure can bend fins and make airflow worse. If possible, spray from the inside out.

If your fins are bent, a fin comb can help straighten them (go slow).

Step 2: Check the Cooling Fan

If the condenser is clean but the A/C still fails at idle, the fan is the next big suspect.

- Start the engine and turn the A/C to max cool, blower on high.

- Watch the fan and listen.

For electric fans:

- The fan should turn on when the A/C runs (or shortly after).

- If the fan does not spin, check the fuse, relay, connector, and ground.

- If power and ground are good, the fan motor may be bad.

For engine-driven fans with a clutch:

- A good fan clutch pulls more air when hot or when the system needs cooling.

- If the fan never seems to pull strong air at idle, the clutch may be weak.

Safety note: Keep hands, tools, and loose clothing away from spinning fans and belts.

3 Other Reasons Your AC Fails at Idle

If airflow and the fan are good, look at these next. These are still common, but a bit more technical.

Reason 1: Low Refrigerant Charge

A/C needs the right amount of refrigerant. A small leak can make the system “almost work.” A Freon leak in off-road machinery is a frequent cause of this problem.

Why Does Low Refrigerant Cause This?

A/C systems use pressure switches for protection. If pressure is too low (or sometimes too high), the system can shut the compressor off.

With low refrigerant:

- At idle, the system may not reach a stable pressure, so it shuts down.

- At higher RPMs, the compressor spins faster and can “barely keep up,” so it cools while moving.

Simple idea: it’s like trying to drink through a straw with a tiny hole—sometimes you get a little, sometimes you don’t.

How to Check for Low Refrigerant

The correct way is with A/C manifold gauges and the proper procedure.

What you can do safely:

- Look for oily, dirty wet spots around hose fittings, the condenser, and the compressor (oil often leaks with refrigerant).

- Check for damaged hoses or rubbed-through lines.

Avoid “guessing” with random recharge cans. Overcharging can also cause problems.

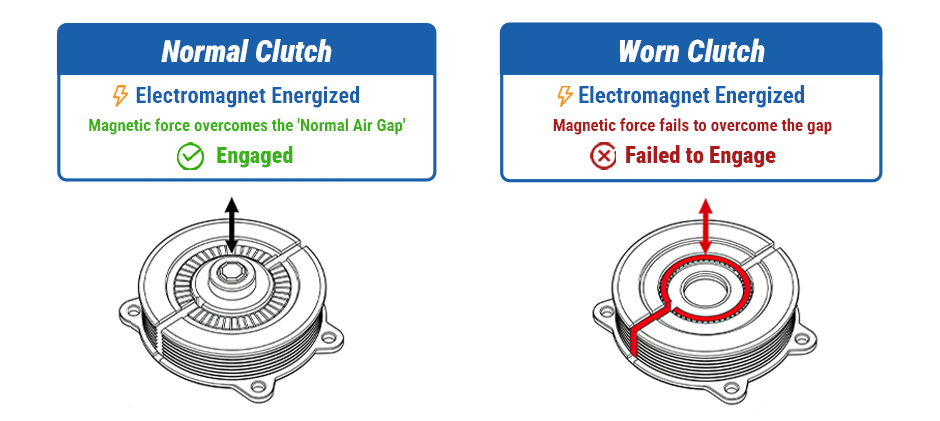

Reason 2: A Worn Compressor Clutch

The compressor is belt-driven, but it only turns when the electromagnetic clutch engages.

How Does the Clutch Affect the AC?

Over time, parts wear, and the clutch air gap can get too big. The magnet may not be strong enough at idle (lower alternator output and lower RPM). When you rev the engine, voltage and speed increase, and the clutch may finally grab.

How to Diagnose a Worn Clutch

- Listen for the click. Turn A/C on/off at idle. You should hear a clear “click” when it engages.

- Watch the clutch face. The outer plate should spin when engaged.

- Try the RPM test. If it won’t engage at idle but engages at higher RPM, the clutch gap or clutch coil may be the issue.

(Some machines allow air-gap adjustment with shims; others need clutch or compressor replacement.)

Reason 3: Electrical System Weakness

A/C needs good electrical power, especially for:

- compressor clutch

- condenser/cooling fan

- controls

What Electrical Issues Can Cause This?

Common causes:

- weak alternator (charges well at higher RPM, weak at idle)

- bad grounds

- loose or corroded battery terminals

- damaged wiring/connectors

How to Spot Electrical Problems

Use a multimeter at the battery terminals. Our guide explains how to test an alternator with a multimeter in detail.

- Engine off: around 12.6V for a healthy, charged battery.

- Engine running (charging): often around 13.5–14.5V (varies by machine).

If the voltage stays in the low 12s with the engine running and A/C on, charging may be weak. You may also see lights dim when the A/C tries to start.

Your 4-Step Action Plan to Fix the AC

Follow this order. It saves time and avoids replacing good parts.

Step 1: Clean and Inspect

Clean the condenser and the space between it and the radiator. Check:

- bent fins

- packed debris

- belt condition, and belt tension (if your system uses belts)

Step 2: Perform the Fan Function Test

With A/C on:

- Confirm the fan runs when it should

- Confirm it pulls strong airflow

Step 3: Conduct the Compressor Clutch Test

At idle:

- Listen/observe for clutch engagement

- See if it only engages after raising RPM

Step 4: Know When to Call a Professional

If the above checks don’t solve it, you may need:

- refrigerant pressure diagnosis (gauges)

- leak testing

- deeper electrical testing

Refrigerant work often requires the right tools and safe handling.

Final Words

When the A/C only works while driving, the system usually cannot control heat and pressure at idle. In off-road conditions, the most common reason is simple: dirty condenser + weak airflow.

Start with cleaning and airflow checks, then move to the fan, clutch, refrigerant level, and electrical health. With this order, most owners can find the real cause faster—and get cold air back during slow work, not just while moving.