A multimeter test is a simple way to check if a spark plug is healthy on the inside, not just on the outside. This matters a lot for off-road machines (tractors, UTVs, mowers, golf carts, skid steers) because they run in dust, mud, vibration, and heat.

Important safety note: Don’t probe a spark plug or plug wire while the engine is running. Ignition systems make very high voltage. A normal multimeter can’t safely measure that spark voltage, and you can get shocked. Use a multimeter with the engine off to check resistance/continuity. If you want to see the spark while running, use a proper spark tester tool instead.

Why Test a Spark Plug with a Multimeter?

A spark plug’s job is to make a strong spark to ignite fuel in the cylinder. (This is different from diesel engines, which use glow plugs instead of spark plugs to aid in cold starting.) You can see problems like:

- cracked ceramic

- heavy black soot

- oil on the tip

- burned or worn electrodes

But you usually cannot see the condition of the resistor inside many spark plugs. That resistor helps reduce radio/electrical noise (RFI) and also affects how strong and steady the spark is. This is why it’s important to distinguish between issues with the ignition coil vs. the spark plug itself. If the resistor fails, the engine may misfire, start hard, or run weak—even if the plug looks “okay.”

“Your eyes can spot an obvious problem, but the multimeter confirms a hidden one.”

When Should You Test Your Spark Plugs?

Test your spark plugs when the engine starts acting strange, or during regular maintenance. Off-road machines often wear out parts more quickly because they operate under harsher conditions and work harder.

5 Symptoms That Warrant a Spark Plug Test

- Engine Misfires or Stumbles: It may shake, hesitate, or “skip,” especially under load.

- Rough Idle: The engine may sound uneven or unstable when sitting still.

- Difficulty Starting: Longer cranking than normal, especially when cold.

- Reduced Power and Acceleration: Feels slow, weak on hills, or struggles when hauling.

- Increased Fuel Consumption: More fuel is used because combustion isn’t clean.

What Tools Do You Need for the Test?

- Digital multimeter (must have Ω / Ohms and ideally continuity mode)

- Spark plug socket + ratchet (the right size for your machine)

- Gap tool (if you plan to reuse the plug)

- Compressed air or a stiff brush (to clean around the plug before removal)

- Safety glasses and gloves

4 Steps to Test a Spark Plug with a Multimeter

Step 1: Safely Remove the Spark Plug

- Let the engine cool so you don’t burn yourself.

- Clean around the plug with compressed air or a brush. This stops dirt from falling into the cylinder.

- Pull off the plug boot by holding the boot, not the wire. Twist a little, then pull straight off.

- Use a spark plug socket to remove the plug.

Tip: If you remove multiple plugs, keep them in order (cylinder 1, 2, 3…) so you can spot patterns.

Step 2: Perform a Visual Inspection

Look for:

- Cracks/chips in the white ceramic insulator

- Heavy black soot (often rich running or too much idling)

- Wet oil (can point to an oil-control issue)

- Worn, rounded, or melted electrodes

If the plug is physically damaged or badly worn, replace it—even if it passes the meter test.

Step 3: Conduct the Resistance Test

This is the main multimeter test for the spark plug’s internal resistor.

1. Set the multimeter to Ohms (Ω).

- If your meter is not auto-ranging, choose the 20kΩ range.

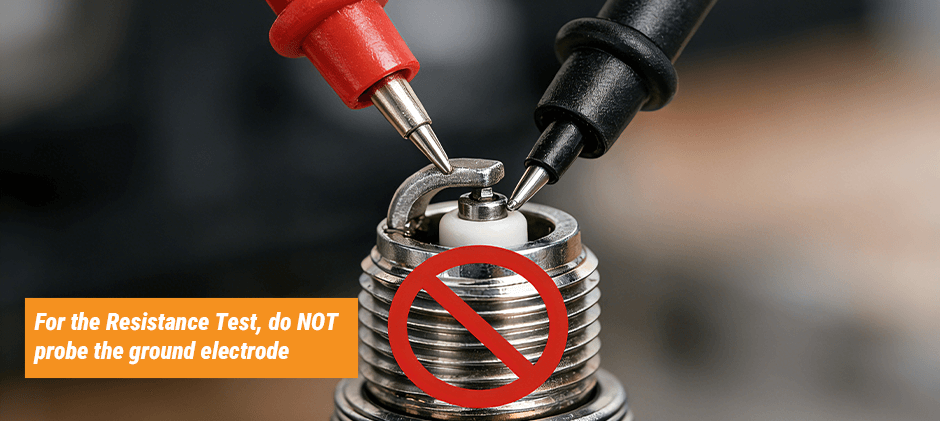

2. Touch:

- One probe to the top terminal (where the plug wire connects).

- Other probe to the center electrode tip at the firing end.

Do not touch the threaded body or ground electrode for this specific resistance test.

Typical results (common resistor plugs):

- A healthy plug often reads about 4,000–8,000 Ω (4k–8k).

- Some plugs may be higher, depending on design, such as their specific spark plug heat range. If you have a spec from the plug maker or service manual, follow that.

What the reading means:

- Good: A steady number in the expected range (example: 5.6kΩ).

- Bad (Open circuit): Meter shows OL / 1 / infinity → internal break → replace the plug.

- Bad (Way out of range): Much higher or lower than normal → likely failing → replace.

Quick note about “testing while running”: this resistance test is done engine off. Testing spark voltage with a normal meter is not recommended.

Step 4: Check for Shorts (Continuity Test)

This test checks if electricity is leaking or “shorting” to the metal shell instead of creating a spark.

Set the meter to continuity mode (it will beep if it detects a connection).

Touch:

- One probe to the center electrode tip.

- The other probe to the metal body/hex/threaded shell.

Interpreting the Results:

- No Beep: This is the expected result for a clean, healthy plug. It means the insulator is doing its job.

- If It Beeps: This indicates a conductive path exists. There are two possible causes:

- Severe Carbon Fouling: The insulator tip is so dirty with carbon that it’s conducting electricity.

- Internal Short: The plug’s internal insulator has failed.

What to do if it beeps?

Before concluding the plug is bad, thoroughly clean the firing end, removing all carbon buildup from the white ceramic insulator. Then, perform the continuity test again.

- If it still beeps after being cleaned, the plug has a confirmed internal short and must be replaced.

- If it no longer beeps after cleaning, the issue was just carbon fouling. The plug is electrically sound and can be reused (after checking the gap).

What to Do After Testing?

If the spark plug is good

- Check the gap with a gap tool and set it to the machine’s spec.

- Reinstall by hand first (avoid cross-threading), then tighten to the correct torque.

If the spark plug is bad

- Replace it. Before you buy, you might want to know how much it costs to replace spark plugs.

- Many owners replace plugs as a set so all cylinders fire evenly.

Extra helpful check (optional): You can also test the spark plug wire/boot resistance with the engine off—probe one metal end to the other. If the wire is damaged, cracked, or reads open (OL), replace it.

Summary

A multimeter is great for checking whether a spark plug is electrically healthy—especially the internal resistor that you can’t see. For safety and correct results, do multimeter tests with the engine off

- Remove the spark plug

- Inspect it visually

- Measure resistance (often ~4k–8kΩ)

- Check for internal shorts with continuity mode

If you want, tell me your machine model/engine type (or the plug part number) and the exact readings you got, and I can help you judge if they’re normal.